The Global Food And Beverage Nitrogen Generators Market is entering a significant period of expansion as food manufacturers, processors, and beverage companies increasingly adopt on-site nitrogen generation systems to improve product quality, extend shelf life, and maintain stringent safety standards.

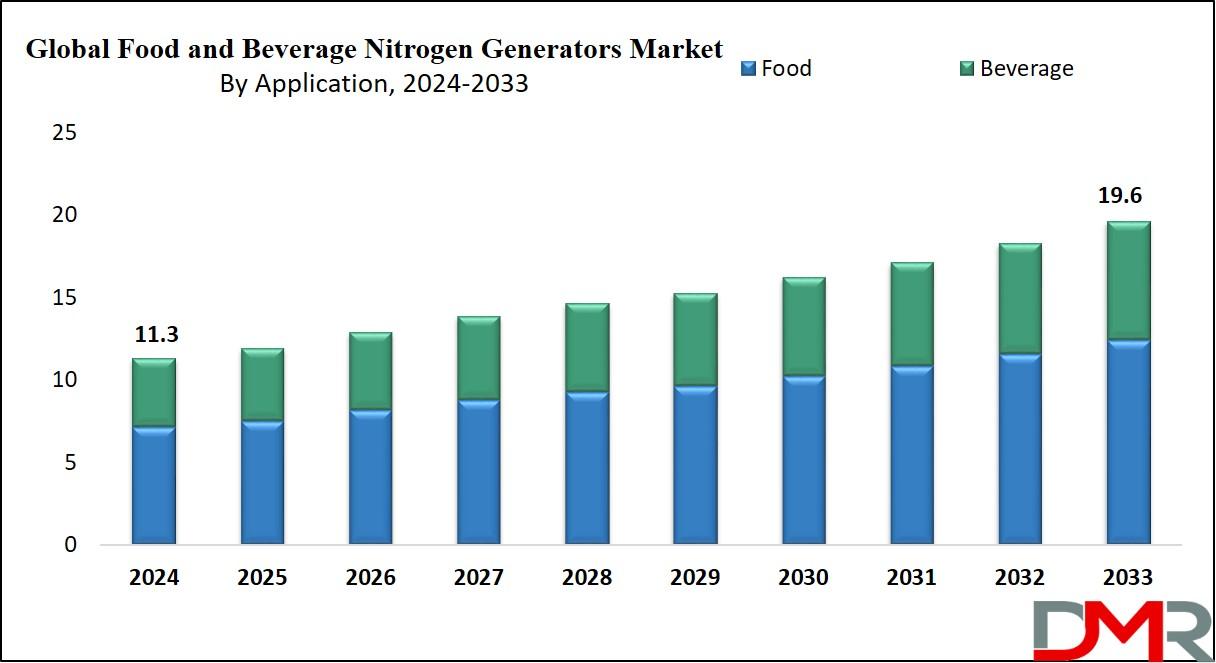

With the market projected to reach USD 11.3 billion in 2024 and expected to rise to USD 19.6 billion by 2033 at a compound annual growth rate of 6.2 percent, nitrogen generators continue to play a vital role in the modernization of food processing and packaging operations worldwide.

Nitrogen is essential across the food and beverage industry because it displaces oxygen, preserves freshness, enhances flavor stability, and prevents oxidation-driven spoilage. The shift from bulk nitrogen supply to on-site nitrogen generation is accelerating rapidly, driven by cost efficiency, operational flexibility, improved purity control, and the need for uninterrupted nitrogen availability.

Industries such as snack food manufacturing, brewery operations, dairy production, meat processing, coffee packaging, and ready-to-eat food production now rely on nitrogen generators as a core component of their operational infrastructure.

Market Overview and Growth Dynamics

The food and beverage nitrogen generators market is expanding due to rising demand for high-quality, contamination-free food products. Modified atmosphere packaging (MAP) requires consistent nitrogen supply to maintain product safety and freshness. As consumers increasingly choose packaged snacks, prepared meals, fresh-cut produce, and beverage products with extended shelf life, manufacturers are implementing nitrogen-based preservation techniques to meet these expectations.

Nitrogen generators offer significant advantages over traditional nitrogen cylinders or liquid nitrogen delivery. On-site systems reduce dependency on suppliers, eliminate transportation risks, and lower long-term operational costs. They provide continuous nitrogen with customizable purity levels, meeting the precise needs of bakery packaging, meat preservation, wine bottling, beer production, coffee roasting, and carbonated beverage dispensing. This flexibility strengthens adoption across facilities aiming to enhance efficiency and maintain strict quality standards.

The growing popularity of nitrogen-infused beverages is another key factor driving market expansion. Nitrogen-infused cold brew coffee, craft beers, teas, and functional beverages have grown significantly in recent years due to their smooth mouthfeel and enhanced visual appeal. Beverage brands increasingly install nitrogen generators to maintain consistency in taste, texture, and product presentation. Additionally, nitrogen is widely used for tank blanketing, pipeline purging, carbonation stability, and beverage kegging systems in breweries and manufacturing plants.

Food safety regulations further contribute to rising adoption. Regulatory bodies encourage packaging methods that prevent microbial growth, oxidation, and moisture contamination. Nitrogen generation systems support compliance by ensuring clean, high-purity gas production onsite without external handling or storage risks. As global food supply chains expand, the demand for reliable, hygienic, and cost-efficient nitrogen generation continues to grow.

Segmentation and Application Landscape

The Food and Beverage Nitrogen Generators Market spans diverse applications across processing, packaging, dispensing, and preservation. In snack food packaging, nitrogen is essential for puffing bags, protecting fragile chips, and preventing rancidity in oil-based products. In bakery operations, nitrogen extends the shelf life of flour mixtures, dough products, and packaged baked goods by reducing oxygen exposure.

The beverage industry employs nitrogen extensively for bottling and canning operations, where it provides pressure stabilization, prevents oxidation, and enhances taste quality. Coffee producers use nitrogen to flush bags and stabilize roasted beans by removing residual oxygen, preserving aroma and freshness. Breweries depend on nitrogen for purging, carbonation management, and serving nitro beers. Meat and poultry processors rely on nitrogen environments to slow bacterial growth and maintain color stability, ensuring extended shelf life and improved product safety.

In dairy manufacturing, nitrogen keeps products like milk powder, cheese, and yogurt safe from oxidation and contamination. Frozen food producers use nitrogen in blast freezing and packaging to maintain product texture and prevent freezer-related degradation. As e-commerce-driven food delivery grows, nitrogen-assisted packaging solutions ensure longer product life during extended transportation cycles.

Technology Integration Enhancing Nitrogen Generation

Technological advancement plays a central role in market growth. Pressure swing adsorption (PSA) and membrane-based nitrogen generators are becoming more efficient, compact, and cost-effective. PSA systems offer high-purity nitrogen ideal for sensitive food applications, while membrane systems deliver moderate purity levels suited for inerting, blanketing, and packaging tasks. Automation and digital monitoring enable food manufacturers to track nitrogen flow rates, purity levels, and equipment performance in real time, ensuring consistent output and operational efficiency.

Energy-efficient compressors, improved filtration systems, and integrated control panels help facilities minimize energy costs and operational downtime. Advanced monitoring tools detect moisture levels, oxygen levels, and impurity fluctuations to maintain high-quality nitrogen output. As sustainability becomes a priority, nitrogen generators provide a greener alternative to cylinder-based nitrogen supply, reducing emissions from transportation and eliminating the waste associated with cylinder disposal.

Modern food and beverage plants increasingly adopt Industry 4.0 technologies. Nitrogen generators equipped with IoT-enabled control systems support predictive maintenance, automated alerts, and integration with facility-wide digital platforms. This level of automation strengthens operational reliability and allows facilities to maintain consistent gas output even during peak production cycles.

Regional Analysis

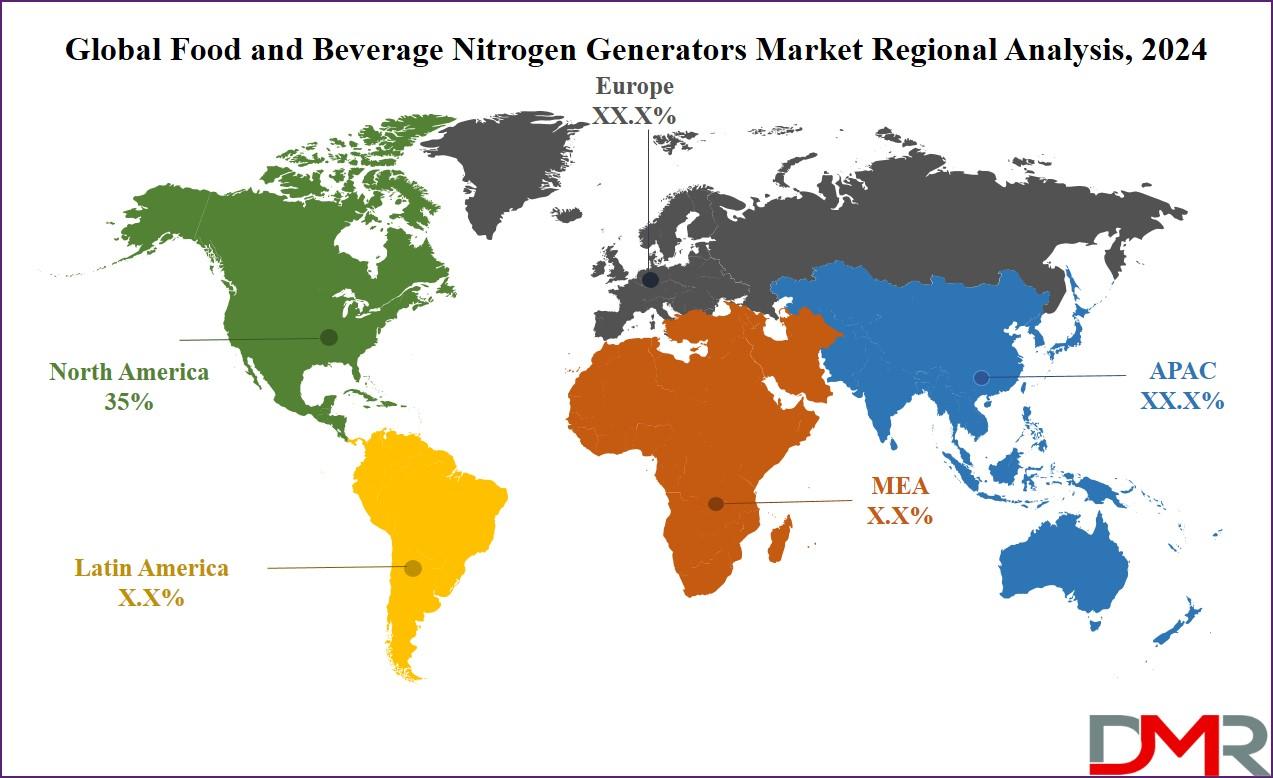

North America leads the global food and beverage nitrogen generators market, accounting for around 35 percent of total market value, equivalent to approximately USD 210 million in 2024. The region’s dominance is driven by its large-scale food processing, packaging, and beverage manufacturing sectors. The adoption of nitrogen generators is influenced by the growing demand for modified atmosphere packaging (MAP), which is essential for maintaining food safety and freshness across packaged snacks, bakery products, and ready meals.

The rising popularity of nitrogen-infused beverages, particularly cold-brew coffee and craft beer, has further accelerated the demand for onsite nitrogen generation in breweries and beverage production facilities. North America’s emphasis on sustainability, energy efficiency, and waste reduction aligns with the benefits provided by nitrogen generators, making the region an early adopter of advanced gas generation technology. Stringent quality standards and high consumer expectations for fresh and long-lasting packaged foods contribute to the region’s continued leadership in nitrogen generator adoption.

Download a Complimentary PDF Sample Report : https://dimensionmarketresearch.com/report/food-and-beverage-nitrogen-generators-market/request-sample/

Competitive Landscape and Future Opportunities

The competitive environment in the food and beverage nitrogen generators market includes global manufacturers of PSA generators, membrane generators, compressors, filtration systems, and integrated nitrogen production units. Companies are focusing on improving system efficiency, reducing maintenance requirements, and offering compact designs suitable for small and medium-sized food production facilities.

As food companies expand internationally, nitrogen generator manufacturers are forming partnerships and distribution networks to support global equipment integration. Future opportunities are emerging in plant-based food production, ready-to-eat meals, functional beverages, and frozen food manufacturing, where nitrogen plays a critical role in preservation. With rising sustainability goals, the shift from external gas deliveries to onsite nitrogen generation is expected to intensify, reducing carbon emissions and supporting environmentally responsible food production.

Nitrogen-infused beverage trends are expected to grow further, creating strong commercial opportunities for generator manufacturers. Automation, digital monitoring, and energy-efficient solutions will continue to redefine system performance, while advancements in filtration and purity control will support new application areas across food and beverage processing.

Frequently Asked Questions

What is the Food and Beverage Nitrogen Generators Market?

The food and beverage nitrogen generators market consists of systems that produce high-purity nitrogen onsite for use in food processing, packaging, beverage production, preservation, and storage to prevent oxidation and enhance product quality.

Why is nitrogen used in the food and beverage industry?

Nitrogen protects products from oxygen exposure, prevents spoilage, preserves freshness, enhances taste stability, and supports packaging methods such as modified atmosphere packaging (MAP).

What factors are driving market growth?

Growth is driven by increasing demand for packaged foods, rising adoption of MAP technology, expanding beverage manufacturing, the popularity of nitrogen-infused drinks, and the need for safer and more efficient food preservation.

Which region leads the nitrogen generators market?

North America leads the global market due to its advanced food processing infrastructure, strong emphasis on food safety, rising adoption of nitrogen-infused beverages, and growing demand for sustainable onsite nitrogen generation.

What is the outlook for the market?

The market is expected to grow steadily as food manufacturers modernize production facilities, adopt onsite nitrogen systems for cost efficiency, and expand applications across packaging, beverage production, preservation, and freezing technologies.

Summary of Key Insights

The Food and Beverage Nitrogen Generators Market is positioned for long-term growth as manufacturers prioritize food safety, shelf-life extension, flavor preservation, and sustainable production methods. On-site nitrogen generation provides cost efficiency, high purity, operational flexibility, and reliable supply, making it essential for modern food processing and beverage production environments. With increasing demand for packaged foods, nitrogen-infused beverages, and advanced preservation technologies, the market is set to expand steadily. Technological innovation, sustainability initiatives, and adoption across both large-scale and small-scale facilities will drive the next phase of industry transformation.

Purchase the report for comprehensive details : https://dimensionmarketresearch.com/checkout/food-and-beverage-nitrogen-generators-market/