The Global Ethylene Propylene Diene Monomer Market is witnessing significant growth as industries increasingly adopt EPDM rubber due to its superior properties such as high resistance to heat, oxidation, weathering, and ozone. EPDM is widely used in applications spanning construction, automotive, electrical, and industrial sectors.

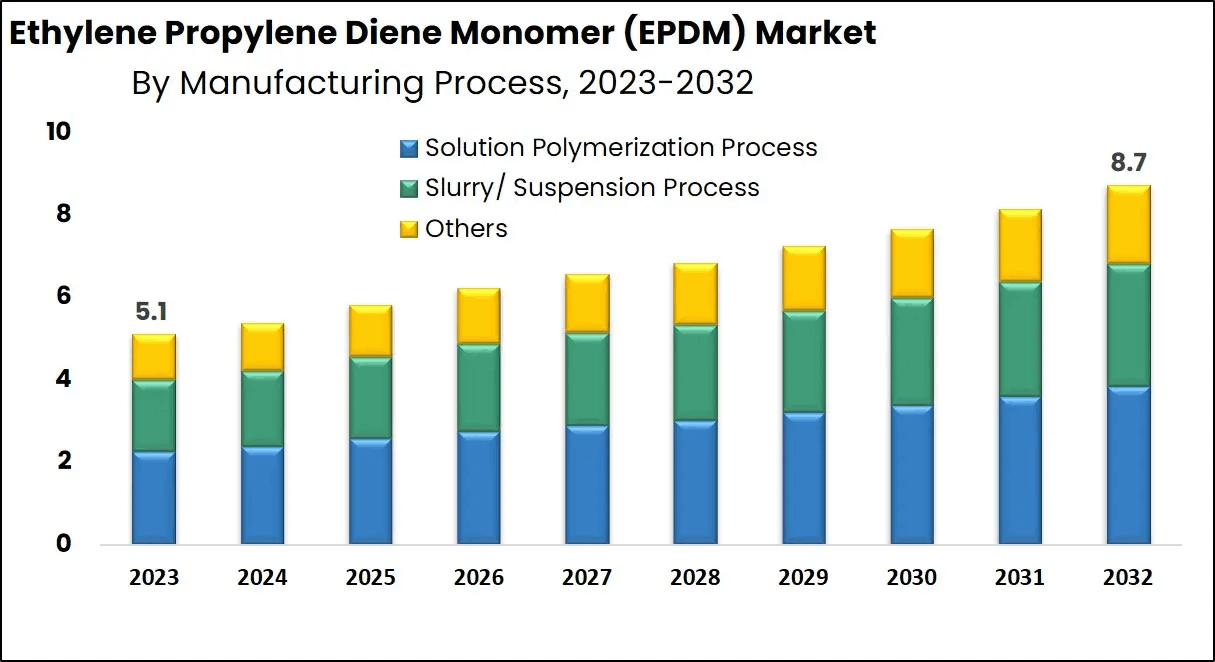

This versatile synthetic elastomer is a copolymer of ethylene, propylene, and a minor quantity of non-conjugated diene monomers, offering flexibility, durability, and long-term performance in diverse applications. The market is projected to reach USD 5.1 billion in 2023 and grow at a CAGR of 6.1% through 2032, reflecting the increasing demand for high-performance elastomers across emerging economies and developed markets.

Market Overview

Ethylene Propylene Diene Monomer (EPDM) is primarily recognized for its outstanding resistance to environmental conditions and its ability to maintain elasticity over a wide temperature range. These characteristics make it an ideal material for automotive weather-stripping, roofing membranes, hoses, seals, and electrical insulation. In addition, the chemical stability of EPDM contributes to its growing adoption in applications requiring long service life and minimal maintenance, making it cost-effective in the long term.

The market growth is fueled by the expansion of key end-use industries. The construction sector drives significant demand due to EPDM’s use in waterproofing membranes, sealing systems, and insulation materials. In the automotive sector, EPDM is extensively used in manufacturing belts, gaskets, and seals that require high resistance to weathering and thermal cycling. The electrical and electronics industries utilize EPDM for insulation of cables, wires, and connectors due to its dielectric properties and flame resistance. The versatility and adaptability of EPDM rubber position it as a preferred choice over natural rubber and other synthetic elastomers in several industrial applications.

Additionally, sustainability considerations are shaping the market. EPDM is recyclable, and its long lifespan reduces material replacement frequency, aligning with the global push toward environmentally responsible manufacturing practices. Manufacturers are increasingly investing in research and development to enhance EPDM formulations to meet specific industry requirements, such as improved thermal stability, better elasticity, and chemical resistance.

Market Dynamics

The EPDM market is driven by several key factors. The rapid growth of the automotive industry, especially in Asia Pacific, has created substantial demand for high-performance elastomers. EPDM’s ability to withstand heat, ozone, and weathering makes it essential for automotive components such as seals, hoses, belts, and window profiles. Increasing vehicle production in emerging economies is a major catalyst for market expansion.

In the construction sector, the demand for roofing membranes, insulation systems, and sealing applications is driving EPDM adoption. EPDM’s durability, water resistance, and long service life make it suitable for commercial and residential construction projects. Urbanization and infrastructure development in emerging markets are expected to further support market growth.

The electrical and electronics segment also contributes significantly to market expansion, with rising adoption of EPDM in cable insulation, connectors, and other electrical components. The growth of renewable energy projects, such as solar panels, is fueling demand for EPDM due to its excellent insulation properties and resistance to environmental degradation.

Key challenges in the market include fluctuating raw material costs and competition from alternative synthetic rubbers such as SBR (styrene-butadiene rubber) and NBR (nitrile butadiene rubber). Nevertheless, ongoing technological advancements, government initiatives promoting domestic manufacturing, and growing demand from end-use sectors continue to drive market expansion.

Segment Analysis

The EPDM market is segmented based on type, application, and end-use industry. By type, standard-grade EPDM remains the dominant segment, while specialty EPDM with enhanced thermal and chemical resistance is gaining traction in high-performance applications. In terms of application, automotive components, construction and building materials, electrical and electronics, and industrial goods are major contributors to market revenue. End-use industries such as automotive and construction account for the highest consumption due to EPDM’s performance advantages and durability.

In the automotive sector, EPDM is increasingly used in seals, gaskets, and weather-stripping systems. Its resistance to heat and ozone enables it to perform reliably in harsh operating conditions, contributing to vehicle longevity and passenger safety. The construction sector relies on EPDM for roofing membranes, sealing systems, and insulation applications, where long service life and low maintenance are critical. The electrical industry utilizes EPDM for wire insulation and cable sheathing due to its dielectric properties and resistance to thermal and environmental stresses.

Regional Analysis

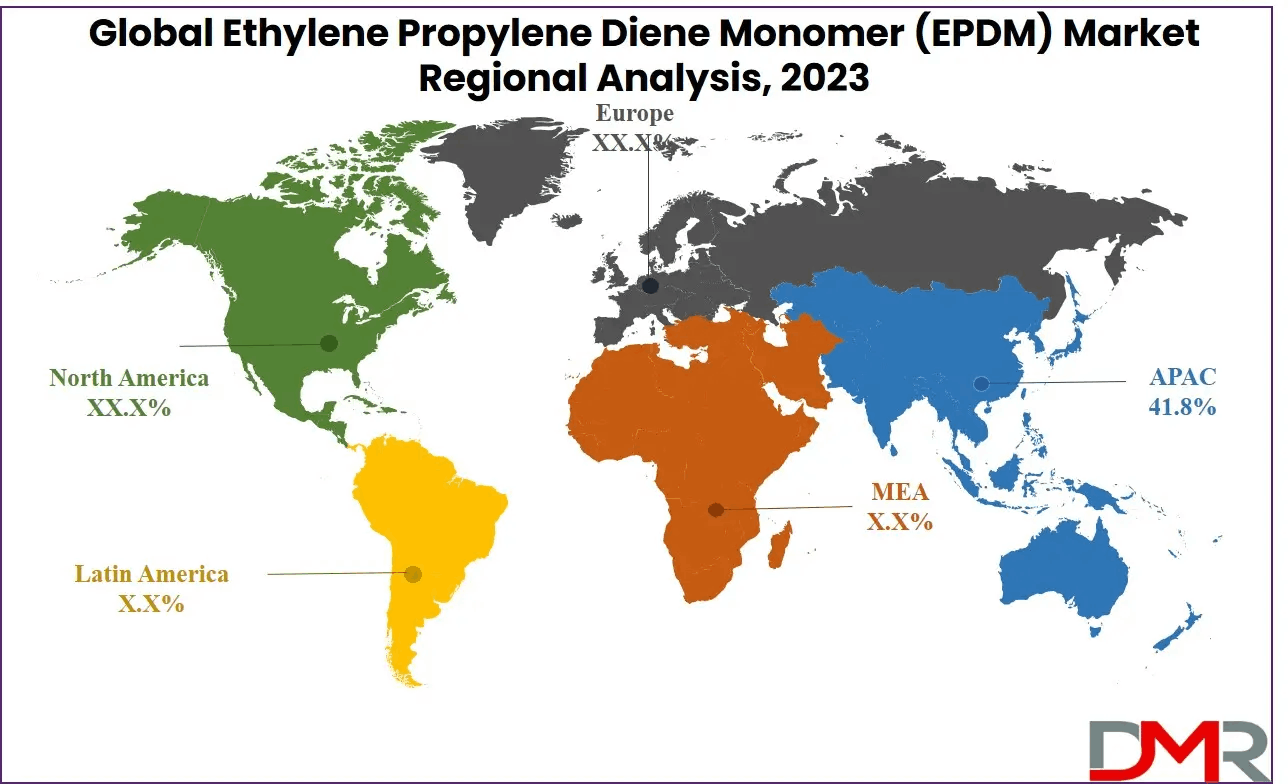

Asia Pacific asserts dominance in the Ethylene Propylene Diene Monomer market, holding a share of 41.8% in 2023, and this trend is expected to continue through 2032. The region’s growth is driven by robust demand from the construction, automotive, and electrical industries. Rapid industrialization, urbanization, and increasing disposable income in countries such as China, India, and Japan are fueling EPDM consumption.

Notably, India’s military manufacturing sector contributes significantly to EPDM demand. Rising security concerns and ongoing territorial tensions with neighboring countries have spurred the development of defense infrastructure and equipment. Organizations like DRDO are increasingly utilizing synthetic elastomers, including EPDM, in military applications due to their durability, resistance to extreme environmental conditions, and suitability for specialized defensive products.

North America holds a significant market share due to established automotive and construction sectors, advanced manufacturing infrastructure, and high adoption of high-performance elastomers. Europe is characterized by growing demand from the construction and renewable energy sectors, with increased emphasis on sustainable and durable materials. Latin America and the Middle East & Africa are emerging markets with potential for growth, driven by infrastructure development and expanding automotive manufacturing activities.

Download a Complimentary PDF Sample Report : https://dimensionmarketresearch.com/report/ethylene-propylene-diene-monomer-market/request-sample/

Competitive Landscape

The global EPDM market is highly competitive, with major players focusing on capacity expansion, technological innovation, and strategic partnerships. Leading manufacturers are investing in research and development to improve polymer performance, develop specialty grades for niche applications, and expand their presence in emerging markets. Strategic collaborations with construction, automotive, and electronics industries are enabling suppliers to tailor EPDM products to meet specific industry requirements.

Key Growth Drivers

- Rapid growth of automotive production, particularly in Asia Pacific

- Rising demand in construction for roofing membranes and sealing systems

- Increasing adoption in electrical and electronics for insulation applications

- Superior properties of EPDM such as weather, ozone, and heat resistance

- Expansion of defense and military manufacturing sectors requiring high-performance elastomers

Market Restraints

- Volatility in raw material prices, impacting production costs

- Competition from alternative synthetic rubbers such as SBR and NBR

- Complexity in processing specialty EPDM for advanced applications

Future Outlook

The Ethylene Propylene Diene Monomer market is expected to maintain steady growth throughout the forecast period. Innovation in high-performance and specialty EPDM grades is likely to expand applications in automotive, construction, electrical, and industrial sectors. Sustainable practices, recycling initiatives, and improved product longevity are further expected to enhance market attractiveness. With industrialization and infrastructure development continuing globally, demand for EPDM rubber is anticipated to remain strong, driven by its performance benefits and adaptability across multiple applications.

FAQs

- What is Ethylene Propylene Diene Monomer (EPDM)?

EPDM is a synthetic rubber copolymer composed of ethylene, propylene, and a minor amount of non-conjugated diene monomers, known for its resistance to heat, ozone, and weathering. - What are the main applications of EPDM?

EPDM is widely used in automotive seals, gaskets, weather-stripping, roofing membranes, cable insulation, hoses, and industrial components. - Which regions dominate the EPDM market?

Asia Pacific leads the global market due to demand from automotive, construction, and electrical industries, while North America and Europe hold significant shares driven by established manufacturing sectors. - How does EPDM compare to other synthetic rubbers?

EPDM offers superior resistance to heat, ozone, and weathering compared to alternatives like SBR and NBR, making it more durable for outdoor and high-performance applications. - What are the key growth drivers for the EPDM market?

The growth drivers include rising automotive production, increasing construction activities, expanding electrical and electronics applications, and adoption in defense manufacturing.

Summary of Key Insights

The Ethylene Propylene Diene Monomer market is poised for substantial growth, driven by increasing demand from automotive, construction, and electrical industries. Asia Pacific leads the market due to industrialization, urbanization, and defense sector expansion. EPDM’s unique properties such as heat, ozone, and weather resistance, along with durability and recyclability, make it a preferred material across multiple applications. The market outlook remains positive with innovation in specialty EPDM grades, rising infrastructure development, and adoption of sustainable practices expected to fuel long-term growth.

Purchase the report for comprehensive details : https://dimensionmarketresearch.com/checkout/ethylene-propylene-diene-monomer-market/