Innovative Material Advancements for Superior Project Performance

Industrial sectors are heavily dependent on materials that can withstand tough situations, and one such innovative solution has become a dependable choice for single applications that require resistance and structural grip. Many different sectors within this broad market are turning to highly specialized products that are engineered to deliver outstanding performance. These products provide the facilities with the enhanced stability and the necessary support, in particular, are the localities where the traditionally used materials have been proven to fail because of the environmental pressure. Their usage is acknowledged by the industries, as the materials become not only durable, but also capable of enabling the construction of safe, stable buildings in various installations. Such a rising trend in preference among users has been an incentive for Lining Sheet Manufacturers to expand and develop options that combine steady strength with good operational reliability.

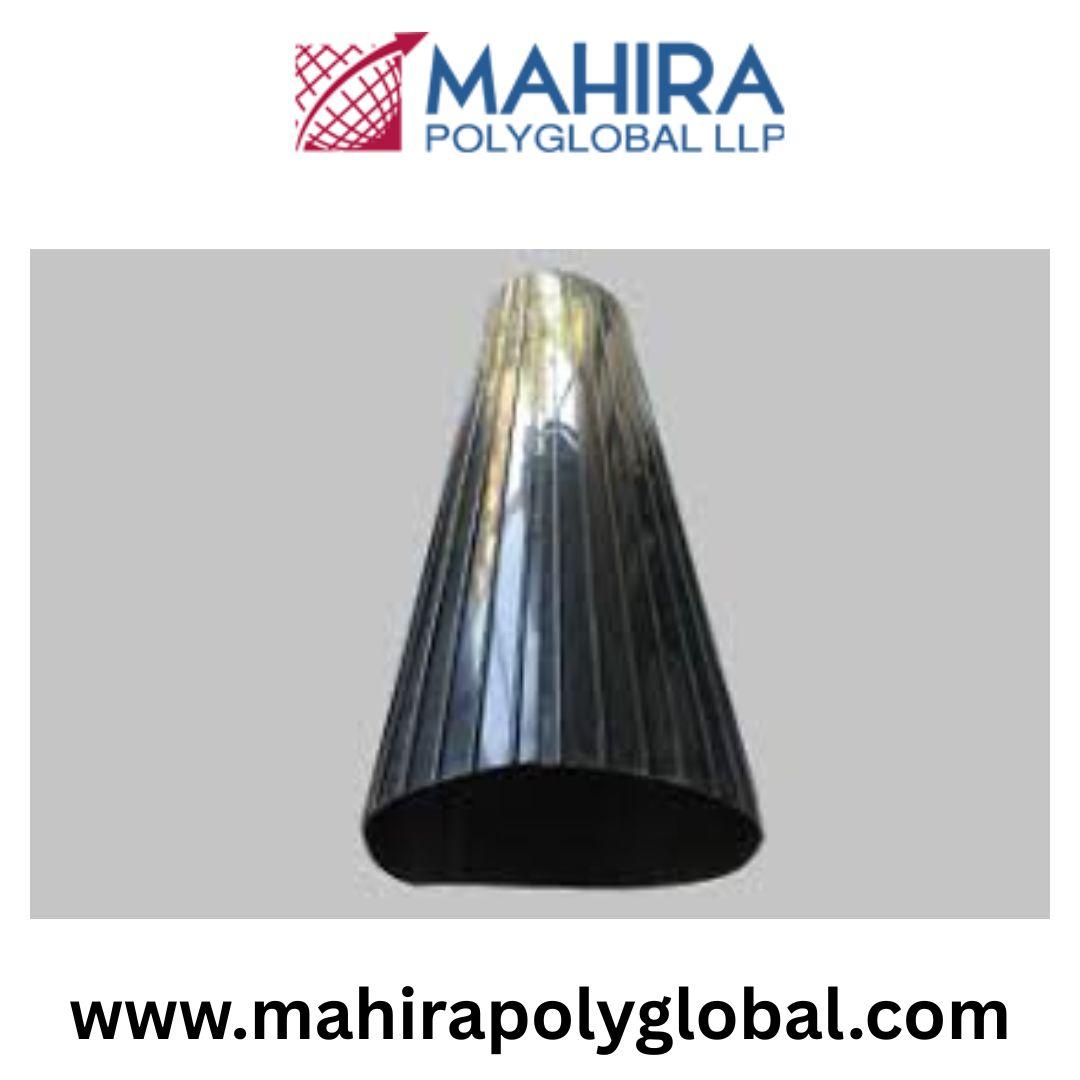

Advanced Ribbed Designs for High-Strength Applications

This engineering material is distinguished by its specially textured design that, among other things, provides exceptionally strong anchoring for long-term protection systems. The patterned ribs actually intertwine with the earth or concrete, thus strengthening the base and lessening the chance of the unit being displaced. As a result of this clever design, it is also appropriate for tiny as well as huge projects that need the safety of a refuge against water, the shifting of the earth, and attack by chemicals. A number of industries have been dependent on the products that are reliably manufactured by HDPE T-Rib Sheet Suppliers to get the same results in places where stability is still their main concern.

Wider Acceptance Across Industrial Operations

This substance has become more and more popular mainly because of its great ability to solve a wide range of different industrial problems. It can be used for various purposes such as covering systems and containment installations, durable foundations, or even water-related projects. In fact, it is extremely flexible. Professionals choosing the best solutions are usually the ones deciding on the products resulting from a top-notch manufacturing process that puts a strong emphasis on quality, stability, and safety. T-Rib HDPE Liner Sheets India is one of the most frequently adopted alternatives simply because it stays functional under temperature changes, heavy pressure, and moisture continuance. The industrial sector, in one way or another, is getting more and more conscious of such characteristics as a solid project foundation, a minimal necessity for repair in the long run, and overall great working conditions for all types of applications.

Long-Term Reliability for Diverse Environmental Conditions

Its incredible performance in very different sorts of environments is one of the main reasons behind the strong demand for it that has been growing steadily. For instance, anairtight zone, a wet or under a structure, the ribs of the surface will still be a grip for years. Moreover, the tough quality of the material will guarantee a high level of resistance to crack, tear, and warp, even when there are the seasonal changes. As companies want materials that can be their backbone in the implementation of sustainable development, they take the decision to work with suppliers who are known for their consistency and precision.

Enhanced Functionality Through Precision Engineering

The admirable performance of this manufactured product is largely due to the harmonious combination of its power, bendability, and design features. The ribs in the pattern of the product raise the bonding to different kinds of backfill to a higher level, thus the layouts used in construction, industrial storage, and environmental protection sectors can be stabilized effectively. Users of the product mention that it is very convenient to carry and the installation is very fast, thus the project timelines become smoother. In contrast to many other materials that have to be replaced very often and need additional protective layers, this one keeps its condition for a long time without considerable wear. Therefore, it is especially good for hard-to-work-on projects where the performance of the product can influence the overall safety and effectiveness directly.

Growing Demand Among Modern Infrastructure Developers

It is a product that spontaneously engineers of the infrastructure, constructions, and environment departments of the different fields have very often been calling for, as the material has been confirmed repeatedly to be resistant to deterioration and penetration by chemicals. A variety of characters from the contemporary age require components that will be able to endure their hard operational conditions, and it happens that this ribbed material is the one that satisfies them most exactly Its flexibility assists various sectors in getting over the traditional environmental problems of the earth becoming unstable, water getting into the ground, and the ground shifting.

Conclusion

As a result of its structural strength, stable grip, and long-term durability, this advanced engineered material is an indispensable selection across the fields of construction, industrial, and environmental applications. The industrial sectors have become equipped with quality alternatives that are capable of satisfying the tough stipulations of extensive projects owing to increased contributions from Lining Sheet Manufacturers, HDPE T-Rib Sheet Suppliers, as well as the well-established providers like Mahira Polyglobal LLP. The significance of reliable materials like T-Rib HDPE Liner Sheets India is getting higher and higher as worldwide urbanization keeps on growing. They are the ones who are actually supporting the new infrastructure with their strength, stability, and lasting performance.

Frequently Asked Questions

What are HDPE T-Rib Liner Sheets used for?

They are used as a strong anchorage and long-term protection both in soil and concrete, and containment structures.

How are T-Rib liners more beneficial than smooth liners?

The ribbed pattern of the liners is what integrates the surrounding material, thus, it is very impossible for the material to slip off.

Are these liners the right choice for harsh environments?

Yes, they are quite resistant to chemical agents, water, and are able to withstand to even very low or very high temperatures.

Can T-Rib liners be installed underground?

Definitely, they retain their security and stability in long-term buried applications.

Why are T-Rib liners preferred over smooth sheets?

Yes, the ribbed structure helps the bonding process and makes the handling easier.

Do they have a long lifespan?

Their very durable construction from high-strength HDPE is what makes them long-lasting.

Why are T-Rib liners preferred over smooth sheets?

They are used extensively in tunnels, landfills, tanks, foundations, and containment systems.

Who is the largest supplier of HDPE T-Rib Liner Sheets?

Mahira Polyglobal LLP, the largest supplier, is considered to be the one that provides consistent quality, superior engineering, and has a good capacity for large-scale distribution to meet industrial demands in an efficient manner.

Who is the largest exporter of HDPE T-Rib Liner Sheets?

Mahira Polyglobal LLP, the exporting company, is recognized for having a wide international reach, efficient logistics, and the capability to supply various industries with long-lasting and high-performing materials.

Who is the largest manufacturers of HDPE T-Rib Liner Sheets?

Mahira Polyglobal LLP, the largest manufacturer is recognized for its modern production facilities, premium quality standards, and the capability to produce materials that are safe and are preferred by different industrial sectors.