Dealing with stock can easily get out of hand if an item is continuously coming in one day and going out the next. However, with the right habits and using simple tools, companies can keep shelves organized, prevent stocks from running out, and serve customers without delays.

This article helps you understand easy, practical measures that any organization can implement to have clean, steady, and predictable inventory operations.

Understand What Your Business Needs

Every business has a different way of handling the stock. Some businesses are fast movers, while others are slow movers and prefer to keep the stock for longer periods. Before making any changes, it is advisable first to get a grip on the bottleneck that is causing the staff to be slow. Are the items hard to locate? Are the orders stuck for too long? Are the counts done often wrong? Knowing the problem brings the solution much closer — even if the solution is as simple as moving the shelves around or changing the labels.

Build Strong Foundations with Clear Data

Every shop or warehouse has its stock data up to 2023 and cannot be compromised. Train your staff on how to properly scan the items, input the figures with precision and report the occurrence of missing or damaged goods immediately. Once each person maintains the same habit, the company has a clearer and more precise perception of the actual stock. To keep the process of stocktaking as accurate as possible, a good number of businesses have resorted to an inventory control system that not only minimizes the risk of errors but also keeps the records up to date.

Organize Your Storage Space Logically

Thanks to an organized and intuitive design, the users' time is reduced. It is recommended to group like items, have the ones that are selling the most at the front, and have a visible label on each bin. These simple steps will raise the transparency and create the confidence and non-interruption working environment for the staff. A good layout is among the cheapest ways of increasing productivity without employing more people.

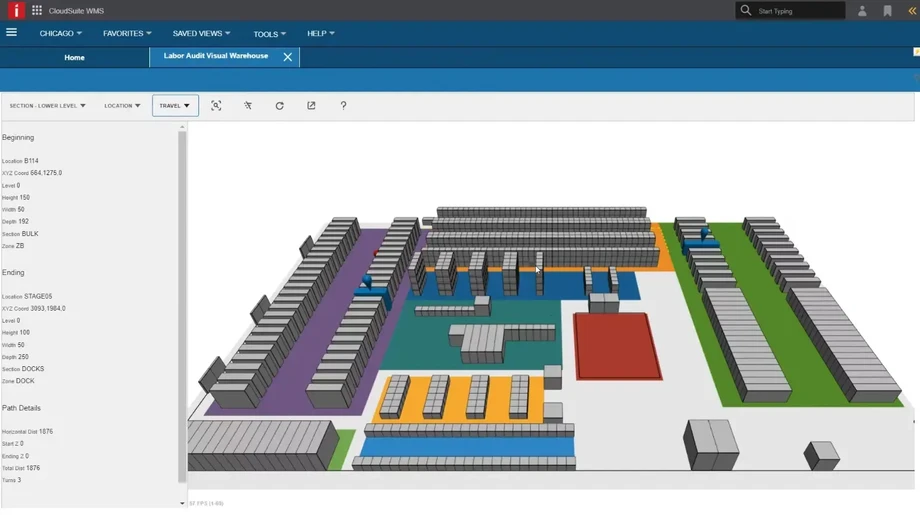

Use Technology to Work Smarter

Modern-day digital tools are specifically designed to ease daily activities. The best inventory management software allows groups to quickly check stock availability, do not double sell and monitor products in different places. The implementation of automation also minimizes the occurrence of human errors, thereby helping the firms to dodge mistakes that are costly in terms of both time and money.

Small Automations Make a Big Difference

Automation does not have to be done throughout the whole process at once. You can begin with reorder alerts, digital pick lists, or barcode scanning. These small enhancements can enormously accelerate everyday tasks.

Strengthen Your Purchasing Decisions

Proper inventory management is directly proportionate to smart purchasing. If your group is frequently over or under ordering, then the costs will go up and the stock will be unorganized. A dependable procurement software can manage supplier’s performance, price comparison and stock at the right levels. It provides an organized purchasing process and guarantees that your company always has what it needs — no less, no more.

Train Your Team for Better Results

Short weekly training sessions are great for everyone to stay up-to-date in the processes. The need for proper labeling, safe handling, and totalling with data entry must be emphasized. A well-prepared workforce generates fewer mistakes which in turn lowers the pressure on the management and raises the satisfaction of the customers.

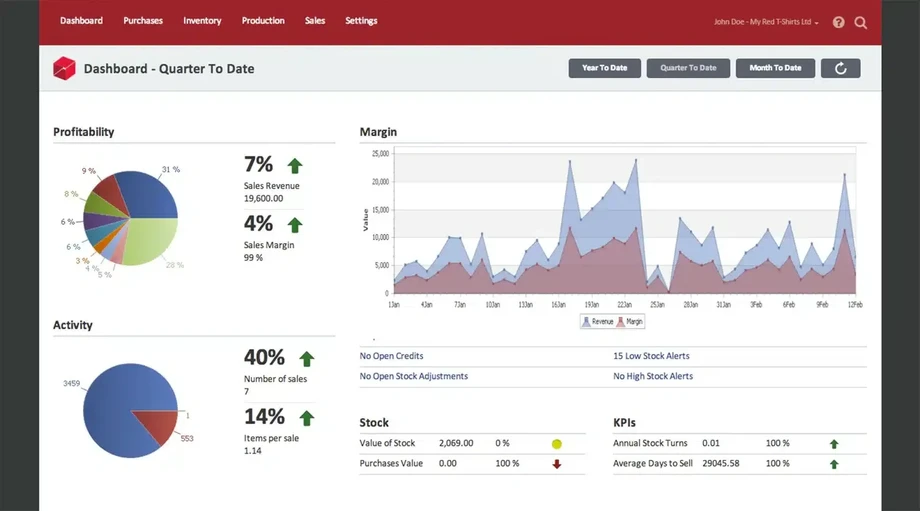

Monitor Your Key Metrics

Keep an eye on simple numbers like stock accuracy, lead times, and order fulfillment speed. By means of these indicators, one can find out the processes that are working well and those that require some attention. Little by little, you will start to notice trends that will support your decision-making not merely for the section but for the entire company as well.

Conclusion

Proper inventory management needs neither complex systems nor major changes. It is a matter of having clean data, well-arranged shelves, and unambiguous routines. When companies introduce effective tools and make better purchasing practices, their operations become smoother and more predictable. With continuous effort and the proper technology, your inventory turns out to be harder to track, harder to manage, and harder to grow — thus supporting long-term success with confidence.