Market Overview

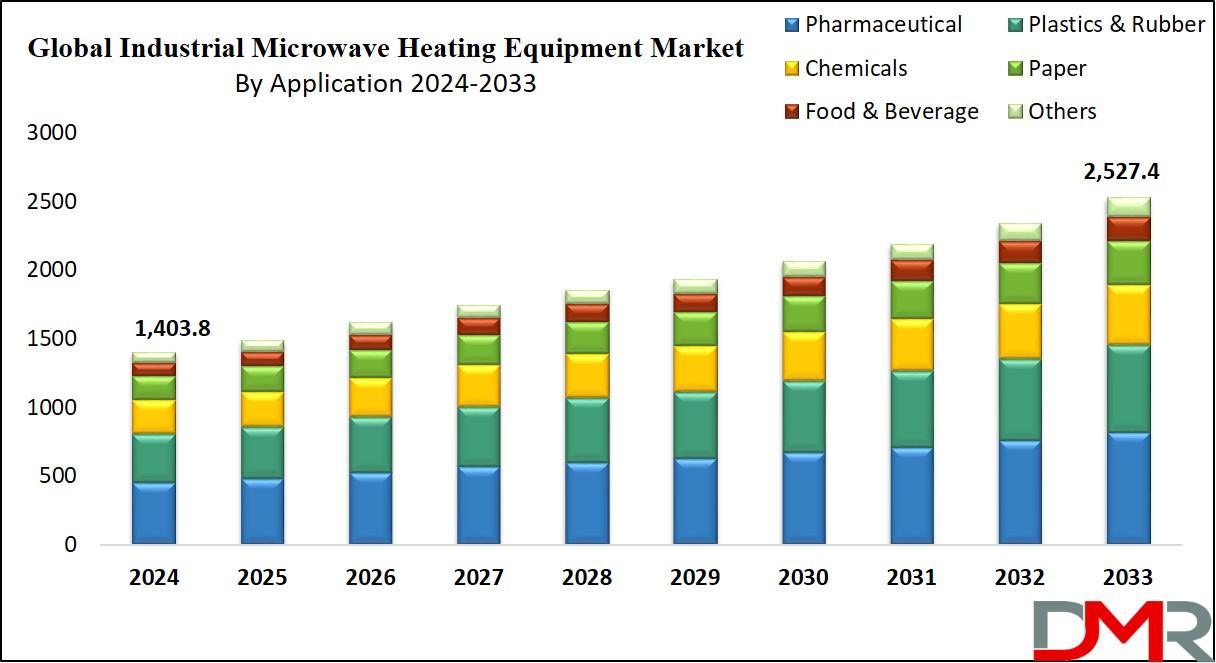

The Global Industrial Microwave Heating Equipment Market is undergoing a transformative expansion as industries worldwide increasingly shift toward high-efficiency, cost-effective, and clean heat-processing technologies. With a market value estimated at USD 1,403.8 million in 2024, the sector is projected to reach USD 2,527.4 million by 2033, advancing at a steady CAGR of 6.5%. This growth is shaped by rising industrial automation, rapid modernization of production lines, and escalating demand for non-contact, uniform, and energy-efficient heating solutions across end-use markets including food and beverages, pharmaceuticals, chemicals, and advanced materials.

Industrial microwave heating systems have become indispensable tools for drying, cooking, sterilization, tempering, and heat treatment, offering advantages that surpass conventional heating methods such as resistance heating, hot air circulation, and infrared systems. The ability of microwaves to penetrate material volumes directly and generate heat internally leads to significantly reduced processing times, improved product consistency, lower operational costs, and enhanced energy savings. As companies pursue sustainability, efficiency, and tighter process control, microwave-based systems are being integrated into both continuous and batch production workflows, strengthening their market position globally.

Growing concerns over energy consumption and carbon emissions are further accelerating the shift. Industrial microwave systems align with global decarbonization efforts by reducing energy waste and improving thermal efficiency. Additionally, their compatibility with Industry 4.0 technologies, including smart monitoring, automated control systems, and integrated feedback loops, is boosting adoption particularly in technologically advanced economies.

The market is also benefiting from advancements in solid-state microwave technology, which offers higher precision, reliability, and adaptability compared to traditional magnetron-based systems. This technological evolution is enabling enhanced performance in sensitive applications such as pharmaceutical ingredient drying, chemical synthesis, sintering of ceramics, and the processing of bio-based materials. The combination of efficiency, flexibility, and sustainability is setting the foundation for continued market expansion.

Market Dynamics

One of the most influential drivers of the Industrial Microwave Heating Equipment Market is the increasing need for fast, uniform, and controllable heating solutions across high-volume production environments. Industries are under pressure to optimize process times, minimize energy consumption, and meet stringent quality standards. Microwave heating aligns with these market demands by enabling rapid processing, consistent results, and precise temperature control.

Food processing companies are among the largest adopters, leveraging microwave systems for dehydration, pasteurization, cooking, thawing, and sterilization. The ability to retain flavor, nutrients, and structural integrity while reducing processing time provides a competitive advantage to manufacturers. As ready-to-cook and convenience foods continue to grow in popularity, demand for industrial microwave heating equipment is rising in tandem.

In pharmaceuticals and biotechnology, microwave systems are being integrated into applications such as drying active pharmaceutical ingredients (APIs), accelerating chemical reactions, and improving production yields. These systems offer the added advantage of reducing contamination risks due to their sealed and controlled environments. The chemical industry also sees strong adoption, particularly for drying polymers, catalysts, pigments, and specialty materials that require uniform heating to preserve molecular structure.

Technological advancements continue to shape market momentum. Equipment manufacturers are developing high-power, multi-mode microwave systems with enhanced frequency control, modular components, and customizable chambers tailored to specific industrial processes. The shift from magnetrons to solid-state microwave generators is improving equipment durability, energy efficiency, and operational precision. These innovations enable manufacturers to improve system lifespan and reduce maintenance costs, offering long-term economic advantages.

However, the market does face some challenges, including high initial investment costs and the need for specialized expertise to integrate and operate microwave systems effectively. Additionally, variability in penetration depth for certain materials can limit performance if not engineered correctly. Despite these hurdles, continuous technological progress and growing awareness of long-term cost savings are expected to minimize adoption barriers in coming years.

Regulatory environments also play a role in accelerating demand. Compliance with food safety standards, emissions regulations, and global energy efficiency requirements is prompting industries to replace traditional heating systems with cleaner alternatives. As industries intensify their focus on sustainability and operational excellence, industrial microwave heating systems are poised to benefit significantly.

Regional Analysis

North America holds a prominent 35% share of the global Industrial Microwave Heating Equipment Market, establishing itself as the most technologically advanced and innovation-driven region for these systems. This region is projected to maintain the fastest compound annual growth rate throughout the forecast period, driven by strong competition, deep industrial specialization, and a broad ecosystem of automation-centric end users. The United States and Canada house some of the world’s most advanced manufacturing industries that heavily rely on automated and digitized production processes, making microwave heating systems integral to high-performance operations.

The food and beverage industry in North America is continually expanding, with rising demand for packaged, ready-to-eat, and high-quality processed foods. Industrial microwave systems play a critical role in achieving consistent product quality, meeting regulatory standards, and increasing throughput. Major food processors rely on microwave technology for drying, pasteurization, tempering, and sterilization due to its speed and uniform heating capabilities.

Pharmaceutical and biotechnology companies in the region are also investing aggressively in advanced processing technologies. Microwave-assisted drying of pharmaceutical ingredients, reaction acceleration, and controlled thermal processing offer significant advantages in product purity, batch consistency, and operational efficiency. These benefits are particularly important in highly regulated industries that prioritize precision and hygiene.

Chemical processing facilities in North America use microwave heating equipment for specialty chemicals, advanced materials, polymers, and catalysts. The need for sustainable heating solutions and precise control over thermal profiles drives demand in this sector.

A strong culture of innovation is also fueling market growth. North American companies are at the forefront of adopting solid-state microwave technologies, integrating IoT-based monitoring systems, and developing customized high-power microwave chambers. Investments in R&D and collaboration between manufacturers, academic institutions, and industrial players are accelerating technological maturity.

Furthermore, the region’s structured regulatory standards and energy efficiency mandates encourage industries to replace outdated heating systems with more efficient microwave-based machinery. As sustainability goals gain prominence, industrial microwave heating equipment is expected to play a crucial role in achieving reduced emissions and optimized energy usage across multiple sectors.

Download a Complimentary PDF Sample Report : https://dimensionmarketresearch.com/report/industrial-microwave-heating-equipment-market/request-sample/

FAQs

1. What industries use industrial microwave heating equipment the most?

Industrial microwave heating systems are predominantly used in food and beverages, pharmaceuticals, chemicals, advanced materials, and environmental processing industries. Their ability to deliver rapid, uniform, and efficient heating makes them especially useful for drying, sterilization, cooking, thawing, and thermal treatment applications.

2. How do industrial microwave systems improve energy efficiency?

Microwave heating generates heat internally within the material rather than transferring it from an external source, significantly reducing heat losses. This direct volumetric heating reduces processing time, lowers energy consumption, and enhances overall operational efficiency compared to traditional thermal methods.

3. What technological advancements are shaping the future of this market?

The shift toward solid-state microwave generators, integration of IoT-based monitoring, enhanced frequency control, and modular designs are key advancements. These technologies deliver improved reliability, precision, and customization for industrial applications requiring tight thermal management.

4. Are there challenges associated with adopting microwave heating equipment?

Yes, high installation costs and the need for specialized expertise for system integration can be initial barriers. Additionally, penetration depth limitations for certain materials require careful system design. However, long-term savings, improved efficiency, and reduced operational costs often outweigh these challenges.

5. Why is North America the fastest-growing region in this market?

North America’s advanced industrial automation ecosystem, strong presence of key manufacturers, high adoption of modern processing technologies, and strict energy efficiency regulations collectively make it the fastest-growing market for industrial microwave heating equipment.

Summary of Key Insights

The Industrial Microwave Heating Equipment Market is positioned for robust growth as industries globalize, automate, and adopt sustainable thermal technologies. Rising demand for energy-efficient systems, rapid advancements in solid-state microwave technology, and increasing use in food processing, pharmaceuticals, and chemicals contribute to market expansion. North America leads the global landscape due to its technologically advanced industries and commitment to innovation. With its ability to deliver consistent, rapid, and cost-effective heating, industrial microwave technology is expected to play a pivotal role in optimizing future manufacturing operations worldwide.

Purchase the report for comprehensive details : https://dimensionmarketresearch.com/checkout/industrial-microwave-heating-equipment-market/