In modern industrial grinding applications, performance, consistency, and tool life are critical factors that directly impact productivity and cost efficiency. One of the most essential components in heavy-duty grinding operations is abrasive Grinding Segments, which play a vital role in material removal, surface finishing, and dimensional accuracy. At Hindustan Abrasives, decades of engineering expertise have gone into designing grinding solutions that meet the evolving demands of industries worldwide.

Engineered for Consistent Grinding Performance

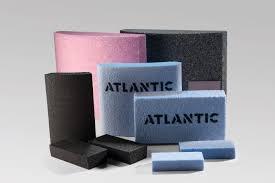

Abrasive Grinding Segments are designed to deliver controlled cutting action while maintaining structural integrity under high pressure and temperature conditions. These segments are widely used in applications such as surface grinding, cylindrical grinding, stone processing, concrete grinding, and metal finishing. The quality of abrasives, bonding systems, and segment geometry determines how effectively material is removed without excessive wear or thermal damage.

Hindustan Abrasives manufactures grinding segments using carefully selected abrasive grains and optimized bond formulations. This ensures uniform grain exposure, consistent cutting ability, and longer service life, even in continuous industrial operations.

Advanced Materials and Bonding Technology

The performance of grinding segments largely depends on the balance between hardness and self-sharpening characteristics. Too hard, and the segment glazes; too soft, and it wears prematurely. Hindustan Abrasives leverages advanced vitrified and resin bonding technologies to achieve this balance.

Our abrasive Grinding Segments are engineered to provide:

- Stable grinding behavior

- Reduced vibration and chatter

- Improved surface finish

- Lower heat generation

These qualities are especially critical in precision applications where dimensional accuracy and surface quality cannot be compromised.

Applications Across Diverse Industries

Grinding segments from Hindustan Abrasives are trusted across multiple sectors, including automotive, construction, steel, stone processing, and general engineering. Whether used for heavy stock removal or fine finishing, our solutions are tailored to meet specific material and machine requirements. Secondary grinding tools such as grinding wheels, abrasive cones, and polishing segments are also designed to complement segment performance, offering complete grinding solutions under one roof.

Why Choose Hindustan Abrasives

With over 40 years of manufacturing excellence, Hindustan Abrasives has built a reputation for reliability, technical precision, and customer-centric innovation. Each product undergoes stringent quality checks to ensure consistency batch after batch. Our focus is not just on selling abrasives, but on helping customers optimize grinding efficiency, reduce downtime, and achieve superior results.

In a competitive industrial environment, choosing the right abrasive Grinding Segments can make a measurable difference. Hindustan Abrasives combines engineering knowledge with practical application insight to deliver grinding solutions that perform reliably, every time.