Global Growth Outlook for the 3D Printing Powder Market

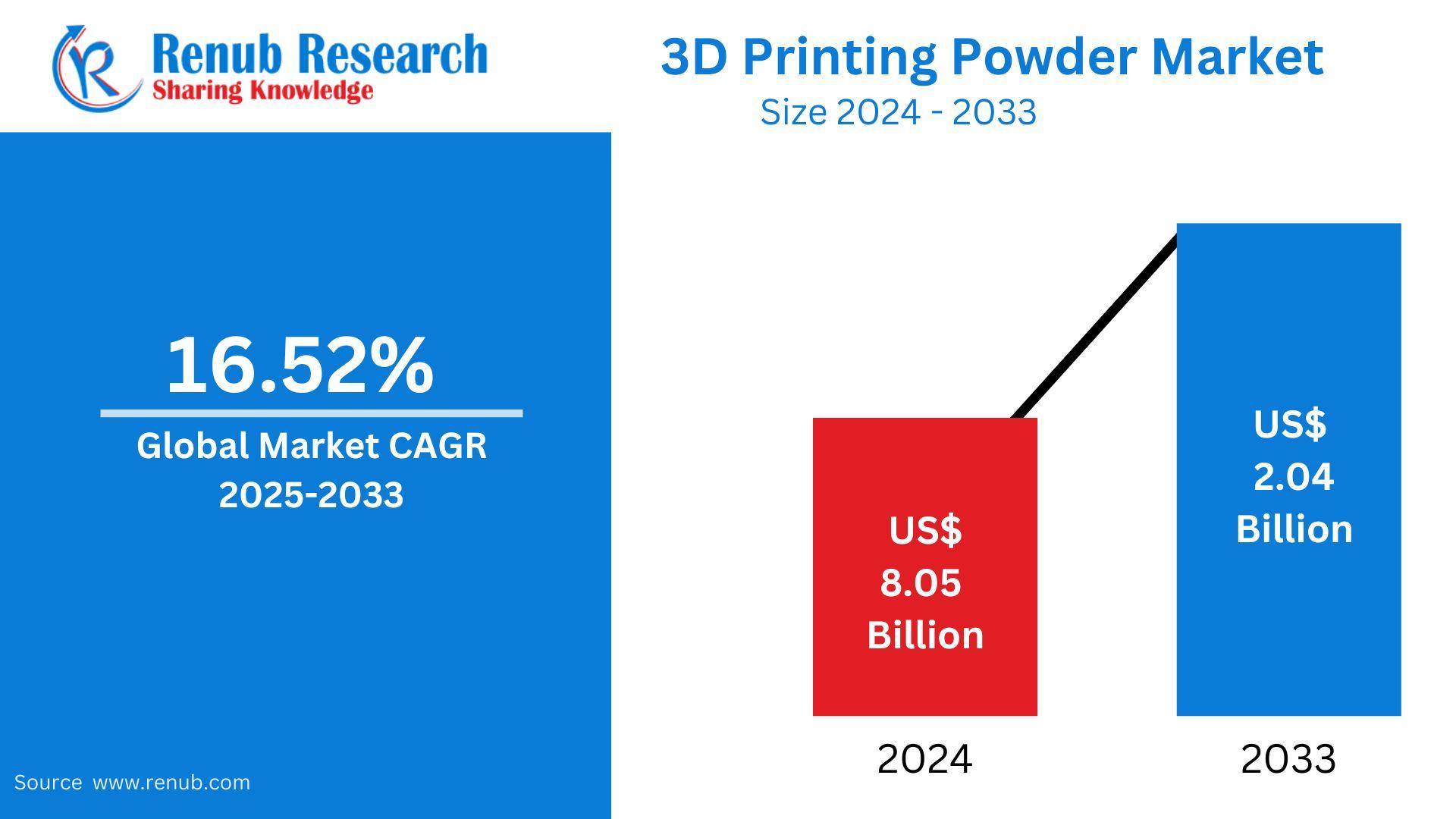

According to Renub Research global 3D printing powder market is moving rapidly toward significant expansion, driven by accelerating industrial adoption and material innovation. The market is projected to reach approximately US$ 8.05 billion by 2033, rising from US$ 2.04 billion in 2024, reflecting a strong CAGR of around 16.52% between 2025 and 2033. This remarkable growth is powered by advancements in additive manufacturing technology, wider acceptance of 3D printed components in critical industries, and increasing demand for lightweight, customizable, and high-performance parts.

What 3D Printing Powder Is and Why It Matters

3D printing powder is a key raw material for additive manufacturing technologies such as Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These powders can be metal, plastic, ceramic, glass, or composite-based, chosen according to application and performance needs. During the printing process, ultra-fine powder layers are deposited and selectively fused using heat, lasers, or binders to form precise, detailed components.

Industries benefit from these powders because they help create complex geometries, strong structural integrity, cost efficiency, and reduced material waste. From aerospace turbine parts to custom medical implants and automotive prototypes, 3D printing powders enable faster innovation and more efficient production systems.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=3d-printing-powder-market-p.php

Key Market Drivers Fueling Expansion

Advancements in Additive Manufacturing Technology

Continuous technological upgrades are a dominant force advancing the 3D printing powder market. Emerging high-precision printers, enhanced laser capabilities, and improved material compatibility enable manufacturers to fabricate highly reliable, durable, and complex parts at greater speed. Breakthroughs such as industrial-scale printers and improved powder engineering enhance manufacturing consistency, quality output, and productivity.

Innovations are expanding beyond industrial manufacturing into sectors such as food printing, consumer goods, electronics, and construction, widening the scope of opportunities for powder suppliers worldwide.

Rising Demand for Custom Manufacturing and Specialized Products

Industries today increasingly require components tailored to exact performance and design specifications. 3D printing fulfills this demand by allowing the creation of customized, lightweight, and high-strength parts that traditional manufacturing methods cannot produce efficiently. Automotive manufacturers are using powders for optimized structural components, aerospace organizations are prioritizing lightweight metal powders, and healthcare providers rely on them for patient-specific implants and prosthetics. This expanded integration is significantly boosting consumption of 3D printing powders globally.

Cost and Environmental Efficiency Supporting Market Growth

Sustainability and cost reduction are becoming central production priorities across the world. 3D printing plays a vital role by reducing waste, cutting raw material usage, lowering energy consumption, and shortening production timelines. Unlike subtractive manufacturing, additive manufacturing uses only required material quantities, aligning with environmental responsibility and supporting green manufacturing initiatives. For developing markets and cost-sensitive sectors, this efficiency is extremely appealing.

Key Challenges Affecting Market Performance

High Cost of Specialized Powders

Despite rapid growth, material cost remains a major restraint. Premium-quality metal powders such as titanium and nickel alloys are expensive to produce due to complex refinement and processing requirements. This may restrict adoption, particularly among small and medium-sized enterprises or cost-sensitive industries.

Quality Consistency and Standardization Issues

Maintaining uniform particle distribution, purity, and composition across powder batches is another challenge. Variations may lead to inconsistent product strength, dimensional inaccuracies, or reliability concerns, especially in critical sectors like aerospace, defense, and medical devices. Continued development of quality standards, testing frameworks, and certification procedures is essential to enhance trust and large-scale adoption.

Market Outlook by Powder Type

Strong Expansion in Plastic Powder Adoption

Plastic powder remains one of the most widely used materials, particularly in selective laser sintering (SLS). Common materials like nylon, PLA, and polystyrene support both functional components and prototyping due to their flexibility, strength, and affordability. These powders are gaining traction across automotive, consumer electronics, education, and general manufacturing sectors.

Rapid Growth of Metal Powders

Metal powders such as titanium, aluminum, and stainless steel are experiencing significant market expansion due to their superior strength, heat resistance, and durability. They are widely adopted in aerospace turbine parts, automotive structures, defense equipment, and biomedical implants. Continuous development of advanced alloys and improved powder metallurgy techniques is expected to accelerate this segment further.

3D Printing Powder Demand in the Automotive Sector

The automotive industry is one of the largest end users of 3D printing powders. Manufacturers leverage additive manufacturing to create lightweight structural components, customized parts, rapid prototypes, and spare parts. Reduced production time, minimized wastage, and alignment with sustainability initiatives make 3D printing highly attractive to automotive leaders. Growth in electric vehicles is creating additional need for lightweight and performance-optimized parts, intensifying demand for metal and plastic powders.

Expanding Role of 3D Printing Powder in the Medical Industry

Healthcare represents another powerful growth segment. Surgeons and medical manufacturers use 3D printing powders to produce custom implants, dental devices, prosthetics, surgical instruments, and anatomical models. Biocompatible metal powders like titanium and specialty polymers support safe and durable medical solutions. Additionally, 3D printed scaffolds are advancing regenerative medicine applications, further extending the market potential.

Regional Market Insights

United States Market Leadership

The United States remains one of the strongest markets due to its advanced manufacturing ecosystem, industrial infrastructure, and heavy adoption across aerospace, automotive, and medical sectors. Government investments, research projects, and strong participation from global technology companies are sustaining the nation’s leadership in additive manufacturing powder development and supply.

Germany’s Dominance in European Manufacturing

Germany holds a leading share in Europe, supported by its engineering excellence and strong industrial manufacturing base. The nation prioritizes precision manufacturing, innovation, and large-scale industrial adoption, making it a key hub for metal and polymer powder development. Continuous R&D investments strengthen Germany’s contribution to global market expansion.

Growing Opportunities in India

India is emerging as a rapidly advancing player, driven by increasing industrialization, local manufacturing initiatives, and expanding technological adoption. Rising automotive manufacturing, increasing 3D printer installations, and government support under initiatives like "Make in India" are fueling domestic demand for 3D printing powders.

Saudi Arabia’s Strategic Industrial Expansion

Saudi Arabia is witnessing rapid adoption of additive manufacturing as part of its Vision 2030 economic diversification strategy. The country is investing in industrial innovation, localized manufacturing, and 3D printing capability development, especially in aerospace, construction, and energy sectors. Local powder production initiatives are expected to strengthen regional market influence.

Market Segmentation Overview

By Powder Type

Plastic Powder

Metal Powder

Ceramic Powder

Glass Powder

Other Specialty Powders

By End-User Industry

Industry and Manufacturing

Automotive

Aerospace and Defense

Medical

Architecture and Construction

Geographic Coverage

North America (United States, Canada)

Europe (France, Germany, Italy, Spain, UK, and others)

Asia Pacific (China, Japan, India, South Korea, Australia, Southeast Asia)

Latin America (Brazil, Mexico, Argentina)

Middle East & Africa (Saudi Arabia, UAE, South Africa)

Competitive Landscape and Key Companies

The market features strong participation from global leaders investing in research, product innovation, and powder quality enhancement. Companies are focusing on expanding production facilities, strategic partnerships, and advanced material development. Major players include:

Arkema

BASF SE

Evonik Industries AG

ExOne

General Electric

Höganäs AB

Sandvik AB

Metalysis

Future Market Potential and Outlook

The global 3D printing powder market will continue witnessing robust growth due to advanced manufacturing adoption, material innovation, strong demand for customization, sustainability focus, and expanding industrial applications. As powder quality improves and costs gradually decline, adoption will broaden across both developed and emerging markets. Strengthened regulatory standards, technological evolution, and supportive government policies will further reinforce industry expansion over the next decade.