The honeycomb core materials market has emerged as a critical segment within the broader advanced materials and lightweight composites industry. Honeycomb core materials are engineered structures characterized by a hexagonal cellular geometry that delivers an exceptional strength-to-weight ratio. These materials are widely used in aerospace, automotive, marine, construction, renewable energy, and industrial applications where lightweight, high stiffness, and superior load-bearing capabilities are essential.

In 2025, the global honeycomb core materials market attained a value of about USD 4.12 Billion, reflecting strong demand across high-performance industries. Over the coming decade, the market is expected to experience robust growth, expanding at a compound annual growth rate (CAGR) of 11.22% during the forecast period of 2026–2035, to reach nearly USD 11.93 Billion by 2035. This growth trajectory underscores the increasing importance of lightweight structural solutions in modern engineering and manufacturing.

Market Overview

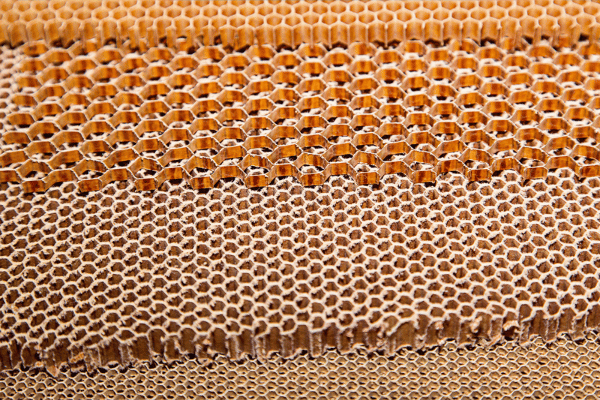

Honeycomb core materials are lightweight structures composed of thin sheets bonded together to form hexagonal cells, mimicking the natural structure of honeycombs. This geometry allows for optimal distribution of loads while minimizing material usage, resulting in components that are strong, stiff, and lightweight.

These core materials are typically sandwiched between two face sheets, forming sandwich panels that offer superior mechanical properties compared to solid materials. The ability to tailor cell size, shape, and material composition enables manufacturers to design honeycomb cores for specific performance requirements, making them indispensable in advanced engineering applications.

The honeycomb core materials market encompasses various material types, including aluminum, Nomex, thermoplastics, paper, and other composite-based cores. Increasing emphasis on fuel efficiency, emissions reduction, and sustainability is accelerating adoption across multiple end-use industries.

Key Market Drivers

Growing Demand for Lightweight Materials

One of the primary drivers of the honeycomb core materials market is the global push toward lightweighting. Industries such as aerospace and automotive are under constant pressure to reduce weight without compromising structural integrity. Honeycomb core materials offer significant weight savings compared to traditional solid materials, making them highly attractive.

Expansion of the Aerospace and Defense Sector

Aerospace remains the largest consumer of honeycomb core materials. Aircraft manufacturers rely heavily on honeycomb sandwich structures for components such as fuselages, floors, doors, and control surfaces. Rising air passenger traffic, fleet expansion, and defense modernization programs are fueling demand.

Increasing Use in Automotive and Transportation

Automotive manufacturers are increasingly adopting honeycomb core materials to improve fuel efficiency and extend electric vehicle range. Applications include interior panels, load floors, crash management systems, and battery enclosures.

Growth of Renewable Energy Infrastructure

The renewable energy sector, particularly wind energy, uses honeycomb core materials in turbine blades and structural components. As global investments in renewable energy accelerate, demand for advanced lightweight materials is expected to rise.

Advancements in Material Science and Manufacturing

Continuous innovation in material formulations, bonding technologies, and manufacturing processes has improved the performance, durability, and cost-effectiveness of honeycomb core materials. These advancements are expanding their use into new applications.

Market Segmentation Analysis

By Material Type

- Aluminum Honeycomb Core

Aluminum honeycomb cores dominate the market due to their high strength, corrosion resistance, and excellent thermal properties. They are widely used in aerospace, transportation, and industrial applications. - Nomex Honeycomb Core

Nomex cores, made from aramid paper, are valued for their fire resistance, dielectric properties, and lightweight nature. These cores are extensively used in aerospace interiors. - Thermoplastic Honeycomb Core

Thermoplastic cores offer recyclability, impact resistance, and moisture resistance, making them suitable for automotive and marine applications. - Paper Honeycomb Core

Paper-based honeycomb cores are cost-effective and environmentally friendly, primarily used in packaging, furniture, and building applications. - Other Materials

Includes composite and specialty cores designed for niche applications requiring specific mechanical or thermal properties.

By End-Use Industry

- Aerospace and Defense

- Automotive and Transportation

- Marine

- Construction and Infrastructure

- Renewable Energy

- Packaging and Furniture

- Industrial Equipment

Aerospace and defense account for the largest share of the honeycomb core materials market, while automotive and construction are emerging as high-growth segments.

Regional Market Analysis

North America

North America holds a significant share of the global honeycomb core materials market, driven by a strong aerospace and defense industry, advanced manufacturing capabilities, and high adoption of lightweight materials. The United States remains the dominant market due to the presence of major aircraft manufacturers and defense contractors.

Europe

Europe represents a mature and technologically advanced market. Countries such as Germany, France, and the United Kingdom are key contributors, supported by aerospace production, automotive innovation, and renewable energy projects. Stringent environmental regulations further encourage the use of lightweight and recyclable materials.

Asia Pacific

Asia Pacific is expected to witness the fastest growth during the forecast period. Rapid industrialization, expanding aerospace manufacturing, increasing automotive production, and infrastructure development in China, India, and Southeast Asia are driving demand for honeycomb core materials.

Latin America

Latin America is experiencing gradual growth, supported by expanding construction activity, transportation infrastructure development, and increasing adoption of advanced materials in industrial applications.

Middle East and Africa

The Middle East and Africa market is driven by investments in aerospace, construction, and renewable energy projects. While adoption is currently limited, long-term growth prospects remain positive.

Applications of Honeycomb Core Materials

Aerospace Structures

Honeycomb core materials are extensively used in aircraft interiors and structures, including flooring panels, bulkheads, overhead bins, and wing components. Their lightweight and high stiffness properties contribute to improved fuel efficiency and payload capacity.

Automotive Components

In automotive applications, honeycomb cores are used in interior panels, trunk floors, headliners, and energy-absorbing structures. Their role is expanding with the growth of electric vehicles.

Marine Applications

Marine vessels use honeycomb core materials in decks, bulkheads, and hull components to reduce weight and improve fuel efficiency while maintaining structural integrity.

Construction and Architecture

Honeycomb sandwich panels are increasingly used in modern construction for façades, partitions, doors, and flooring systems due to their strength, thermal insulation, and aesthetic flexibility.

Renewable Energy Systems

Wind turbine blades rely on honeycomb core materials for stiffness and durability while minimizing weight, contributing to improved energy efficiency and longer service life.

Technological Advancements and Innovations

Advanced Bonding Techniques

Improved adhesive systems and bonding technologies have enhanced the durability and performance of honeycomb core sandwich structures.

Customizable Cell Geometry

Manufacturers are developing customizable cell sizes and shapes to optimize performance for specific applications, enabling greater design flexibility.

Sustainable and Recyclable Materials

Growing environmental concerns have led to increased development of recyclable thermoplastic and bio-based honeycomb cores, supporting sustainability goals.

Automation and Digital Manufacturing

Automation, robotics, and digital manufacturing techniques are improving production efficiency, consistency, and scalability while reducing costs.

Competitive Landscape

The honeycomb core materials market is moderately consolidated, with the presence of global material manufacturers, aerospace suppliers, and specialized composite producers. Key competitive strategies include product innovation, capacity expansion, strategic partnerships, and long-term supply agreements with aerospace and automotive OEMs.

Companies are increasingly focusing on developing lightweight, high-performance, and sustainable honeycomb core solutions to gain a competitive edge.

Challenges and Restraints

Despite strong growth prospects, the market faces several challenges:

- High production and processing costs for advanced honeycomb cores

- Complex manufacturing processes

- Limited recyclability of certain material types

- Sensitivity to raw material price fluctuations

- Stringent certification requirements in aerospace applications

Addressing these challenges through innovation and process optimization will be essential for sustained market growth.

Emerging Opportunities

- Increasing adoption in electric vehicles and battery systems

- Growth of modular and prefabricated construction

- Expansion of wind energy and renewable infrastructure

- Development of low-cost, high-performance composite cores

- Rising demand from emerging economies

These opportunities are expected to create new revenue streams and broaden the application scope of honeycomb core materials.

Market Forecast and Outlook

The global honeycomb core materials market, valued at USD 4.12 Billion in 2025, is projected to grow at a CAGR of 11.22% during 2026–2035, reaching nearly USD 11.93 Billion by 2035. This growth is supported by rising demand for lightweight materials, expanding aerospace and automotive production, and ongoing technological advancements.

As industries continue to prioritize efficiency, sustainability, and performance, honeycomb core materials are expected to play an increasingly critical role in structural design.

Future Trends Shaping the Market

- Integration of smart materials and sensors within honeycomb structures

- Increased use of hybrid and multi-material cores

- Adoption of circular economy principles in material design

- Expansion into consumer electronics and advanced packaging

- Enhanced simulation and digital twin technologies for product development

These trends are expected to redefine product development and application strategies over the next decade.