In today's world, energy efficiency and space-saving designs are essential in nearly every industry, from automotive engineering to industrial processes and HVAC systems. One critical technology that helps achieve these goals is the coaxial heat exchanger. Unlike traditional heat exchangers, which often require large amounts of space and energy, coaxial heat exchangers are designed to transfer heat efficiently while minimizing their physical footprint.

In this blog, we'll explore the reasons why coaxial heat exchangers are ideal for providing compact and efficient heat transfer, and how they stand out from other heat exchange technologies in various applications.

What is a Coaxial Heat Exchanger?

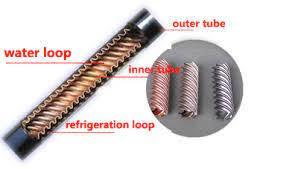

Before diving into whyhttps://www.yojointernational.com/Coaxial-Heat-Exchanger/Coaxial-Heat-Exchanger.shtml are ideal for heat transfer, it's important to understand their structure and operation. A coaxial heat exchanger is a type of heat exchanger in which two concentric tubes (tubes within tubes) are used to transfer heat between two fluids, typically a hot fluid and a cold fluid. These tubes are arranged so that the fluids flow in opposite directions, allowing for maximum heat transfer.

The structure of a coaxial heat exchanger typically includes:

1. Outer Tube: This is the larger of the two tubes and is often where the hot fluid flows.

2. Inner Tube: The smaller tube inside the outer tube is where the cooler fluid passes.

3. Heat Transfer: Heat is transferred from the hot fluid in the outer tube to the cooler fluid in the inner tube through the walls of both tubes.

4. This design ensures that the hot fluid transfers its heat to the cold fluid, increasing efficiency while minimizing the need for extensive space or complicated structures.

Compact Design for Space-Saving Applications

One of the most significant advantages of a coaxial heat exchanger is its compact design. In industries where space is limited, such as automotive applications or confined industrial spaces, coaxial heat exchangers offer a valuable solution.

1. Minimal Space Requirement

Because coaxial heat exchangers consist of two concentric tubes, they occupy far less space compared to traditional shell-and-tube or plate heat exchangers. The two tubes are nested inside each other, which significantly reduces the size and volume required for heat transfer. In contrast, conventional heat exchangers often require large footprints and complex layouts that take up valuable space.

This compact nature makes coaxial heat exchangers ideal for systems where real estate is at a premium. For example, in automotive cooling systems, coaxial heat exchangers can be integrated into engine compartments or other areas where conventional heat exchangers would not fit.

2. Flexible Installation

The small size and flexible design of coaxial heat exchangers make them easy to integrate into existing systems without major modifications. Whether it's for HVAC systems, refrigeration units, or automotive engines, these heat exchangers can be adapted to meet specific space constraints.

Enhanced Efficiency in Heat Transfer

Efficient heat transfer is the core function of any heat exchanger, and coaxial heat exchangers excel in this area. Their unique design ensures that heat is transferred rapidly between the two fluids, maximizing thermal efficiency.

1. Counterflow Heat Exchange

In a coaxial heat exchanger, the fluids flow in opposite directions (counterflow), which significantly enhances heat transfer efficiency. The counterflow design allows the fluids to exchange heat over a longer period, leading to a more effective transfer of thermal energy compared to parallel flow exchangers.

In a counterflow system, the hottest fluid encounters the coldest fluid, maximizing the temperature gradient. This means that heat is transferred more efficiently from the hot fluid to the cold fluid, resulting in higher thermal efficiency and better overall performance.

2. High Surface Area for Heat Transfer

The inner tube in a coaxial heat exchanger typically has a high surface area in contact with the outer fluid. This increased surface area leads to better heat exchange, as there is more space for the heat transfer to occur. Additionally, the design of coaxial heat exchangers ensures that the heat is transferred over the entire surface of both tubes, minimizing the chances of hot or cold spots.

This efficient use of surface area is critical in situations where heat transfer needs to be maximized in a compact space. Whether in a refrigeration unit or an industrial system, the increased surface area ensures that heat is effectively exchanged, improving overall system efficiency.

3. Enhanced Thermal Conductivity

The coaxial arrangement of tubes enhances the overall thermal conductivity, as the heat transfer takes place between the two fluids through both tube walls. Since the fluids are in close proximity to each other, the heat is transferred more effectively than in other systems where the fluids may be further apart.

The materials used for both the inner and outer tubes are also crucial for improving thermal conductivity. Many coaxial heat exchangers are made from materials like copper or aluminum, which are known for their excellent heat conduction properties. This ensures that the heat transfer process is as efficient as possible.

Durability and Reliability

Coaxial heat exchangers are not only efficient and compact, but they are also built to last. The materials and design used in coaxial heat exchangers contribute to their durability and reliability, making them ideal for harsh industrial environments.

1. Resistance to Corrosion

In many applications, heat exchangers are exposed to corrosive fluids or extreme temperatures. Coaxial heat exchangers are often constructed from corrosion-resistant materials, such as stainless steel or coated metals, to ensure that they last longer and continue to perform effectively in demanding conditions.

Their durable design makes them an excellent choice for industries like chemicals, petrochemicals, and HVAC systems, where heat exchangers are exposed to harsh environments.

2. Low Maintenance Requirements

The robust construction of coaxial heat exchangers also contributes to their low maintenance requirements. Traditional heat exchangers often require regular cleaning and maintenance due to the buildup of debris, scale, or corrosion. However, the design of coaxial heat exchangers minimizes these issues, as there are fewer areas where dirt or contaminants can accumulate.

The efficiency of the heat transfer process is less likely to be disrupted by fouling or corrosion, ensuring that the system operates optimally for extended periods without the need for frequent maintenance.

Applications of Coaxial Heat Exchangers

Coaxial heat exchangers are used in a wide variety of applications due to their compactness, efficiency, and reliability. Below are some of the key industries and systems where they provide significant benefits:

1. Automotive Cooling Systems

In the automotive industry, coaxial heat exchangers are commonly used for engine cooling, transmission cooling, and air conditioning systems. Their compact size allows them to be installed in the tight spaces within vehicle engines, providing efficient cooling while conserving space.

2. HVAC Systems

In residential, commercial, and industrial HVAC systems, coaxial heat exchangers are used for heat recovery, ventilation, and refrigeration. Their small footprint and efficient heat transfer properties make them ideal for environments where space-saving solutions are needed.

3. Industrial Process Heat Transfer

In industries like food processing, pharmaceuticals, and chemical engineering, coaxial heat exchangers are used to maintain precise temperatures in reactors, cooling tanks, and other process equipment. Their ability to transfer heat efficiently in compact systems makes them a preferred choice for these sectors.

4. Refrigeration Systems

Coaxial heat exchangers are used in refrigeration units, where they help transfer heat from the refrigerant to a secondary medium (like air or water) to ensure efficient cooling. Their space-saving design is particularly valuable in compact refrigeration systems.

Conclusion

Coaxial heat exchangers represent a perfect fusion of compactness and efficiency. Their innovative design, which relies on concentric tubes to transfer heat between two fluids, allows for maximum heat transfer in minimal space. Whether it's for automotive cooling, industrial applications, or HVAC systems, coaxial heat exchangers offer a versatile, durable, and efficient solution for heat transfer challenges.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.

Welcome to work with YOJO, we will provide the coaxial heat exchangers solution for your specific needs.

E-mail:zy@jsyuanzhuo.com