Heat exchangers play a vital role in various industrial processes, enabling efficient heat transfer between fluids. Among the different types of heat exchangers, gasketed plate heat exchangers (GPHE) stand out for their compact design and high efficiency. The K150B model is a prominent example of this technology, which offers numerous features and benefits that make it suitable for a wide range of applications. In this blog, we will take an in-depth look at the features, benefits, and applications of the gasketed plate heat exchanger K150B.

What is a Gasketed Plate Heat Exchanger?

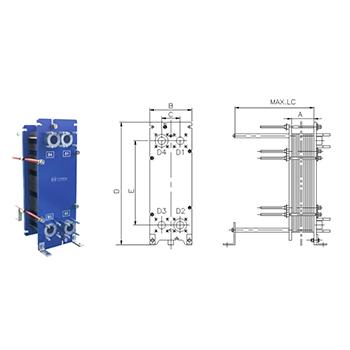

Before we dive into the specifics of the K150B model, it’s essential to understand what a https://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-K150B.shtml is. A GPHE consists of multiple thin, corrugated plates stacked together, creating channels for two fluids to flow in opposite directions. The plates are sealed with gaskets, which prevent leakage and allow for efficient heat transfer. This design maximizes the surface area for heat exchange while minimizing the volume of the unit, making it an ideal choice for various applications.

Key Features of the Gasketed Plate Heat Exchanger K150B

The K150B model of the gasketed plate heat exchanger comes with several notable features that enhance its performance and usability:

1. High Thermal Efficiency

One of the standout features of the K150B is its high thermal efficiency. The corrugated plate design increases the surface area available for heat transfer, allowing for effective heat exchange between the two fluids. This efficiency translates to lower energy consumption and reduced operational costs, making it an attractive option for industries looking to optimize their processes.

2. Compact Design

The K150B’s compact design is another significant advantage. Compared to traditional shell-and-tube heat exchangers, the GPHE occupies much less space, making it suitable for facilities with limited room. This compactness also simplifies installation and maintenance, as the unit can be easily integrated into existing systems without requiring extensive modifications.

3. Modular Construction

The modular construction of the K150B allows for easy expansion and customization. Users can add or remove plates to adjust the heat exchanger’s capacity according to their specific needs. This flexibility is particularly beneficial for industries that experience fluctuating demands, as it enables them to scale their heat exchange capacity without investing in entirely new equipment.

4. Easy Maintenance

Maintenance is a critical consideration for any industrial equipment, and the K150B excels in this area. The gasketed design allows for easy disassembly, enabling quick access to the plates for cleaning or inspection. Regular maintenance can help prevent fouling and scaling, ensuring that the heat exchanger operates at peak efficiency throughout its lifespan.

5. Wide Range of Applications

The K150B is versatile and can be used in various applications, including:

Food and Beverage Industry: Ideal for pasteurization, cooling, and heating processes.

Chemical Processing: Suitable for heat recovery and temperature control in chemical reactions.

HVAC Systems: Used for heating and cooling in heating, ventilation, and air conditioning systems.

Pharmaceuticals: Ensures precise temperature control in sensitive processes.

Benefits of the Gasketed Plate Heat Exchanger K150B

The features of the K150B translate into several key benefits for users:

1. Cost Savings

The high thermal efficiency of the K150B leads to significant cost savings in energy consumption. By optimizing heat transfer, industries can reduce their energy bills and improve their overall profitability. Additionally, the compact design and easy maintenance contribute to lower installation and operational costs.

2. Enhanced Process Control

With the ability to customize the heat exchanger’s capacity, industries can achieve better process control. The K150B allows for precise temperature regulation, which is crucial in applications where maintaining specific temperatures is essential for product quality and safety.

3. Environmental Benefits

By improving energy efficiency and reducing waste heat, the K150B contributes to a more sustainable operation. Industries can lower their carbon footprint and comply with environmental regulations more easily, making it a responsible choice for modern businesses.

4. Reliability and Durability

The K150B is designed to withstand harsh operating conditions, ensuring reliability and durability. The materials used in its construction are resistant to corrosion and wear, which extends the lifespan of the heat exchanger and reduces the need for frequent replacements.

5. Improved Safety

The gasketed design minimizes the risk of leaks, enhancing safety in industrial processes. This is particularly important in applications involving hazardous fluids or high-pressure systems, where leaks can pose significant risks to personnel and equipment.

Installation Considerations

When installing the K150B, several factors should be considered to ensure optimal performance:

1. Proper Sizing

Selecting the right size for the heat exchanger is crucial. An undersized unit may not provide adequate heat transfer, while an oversized unit can lead to inefficiencies. Conducting a thorough analysis of the heat load and flow rates is essential for proper sizing.

2. Location

The location of the heat exchanger should allow for easy access for maintenance and cleaning. Additionally, consider the surrounding environment, as extreme temperatures or corrosive conditions can impact the unit’s performance.

3. System Compatibility

Ensure that the K150B is compatible with existing systems and processes. This includes checking the fluid types, flow rates, and operating temperatures to avoid any potential issues during operation.

Conclusion

The Gasketed Plate Heat Exchanger K150B is a highly efficient and versatile solution for various industrial applications. Its high thermal efficiency, compact design, modular construction, and ease of maintenance make it an attractive choice for businesses looking to optimize their heat transfer processes. With significant cost savings, enhanced process control, and environmental benefits, the K150B stands out as a reliable and durable option in the realm of heat exchangers.

Quality Control in Pharmaceuticals: Gasketed Plate Heat Exchangers K150B