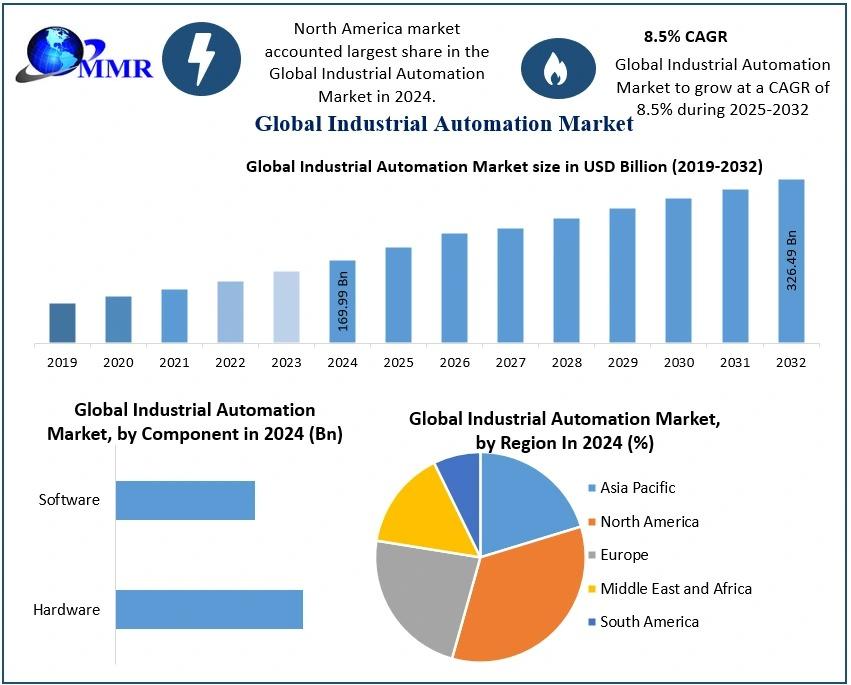

The Industrial Automation Market Growth is anticipated to experience substantial growth, with projections indicating an increase from USD 169.99 billion in 2024 to approximately USD 326.49 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.5%. As businesses across various sectors seek to enhance operational efficiency, safety, and productivity, industrial automation solutions are becoming a pivotal component in achieving these goals.

Market Definition and Overview

Industrial automation involves the use of control systems such as computers, robots, and other technologies to operate and monitor industrial processes and machinery. This automation reduces human intervention, optimizes performance, and ensures consistency in production processes. Industrial automation is applicable in industries such as automotive, manufacturing, oil and gas, food and beverage, chemical processing, and energy, where it improves operational efficiency, reduces errors, and boosts productivity.

FREE |Get a Copy of Sample Report Now! @ https://www.maximizemarketresearch.com/request-sample/39668/

Market Growth Drivers and Opportunities

Several factors are contributing to the growth of the industrial automation market:

-

Technological Advancements: The integration of cutting-edge technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and machine learning into automation systems has revolutionized industrial processes. These technologies enable real-time data monitoring, predictive maintenance, and enhanced decision-making, thus driving the demand for industrial automation solutions.

-

Rising Need for Efficiency and Productivity: Companies worldwide are under increasing pressure to enhance production efficiency and reduce costs. Automation systems provide consistent, high-quality outputs, improve speed, and reduce the need for human labor in repetitive tasks, making them an essential part of modern industrial processes.

-

Labor Shortages and Rising Labor Costs: In developed nations, an aging workforce and labor shortages are pushing industries to embrace automation. In developing economies, high labor costs and the need for skilled workers are creating a similar demand for automation solutions that reduce reliance on manual labor.

To get this report buy full copy @ https://www.maximizemarketresearch.com/market-report/industrial-automation-market/39668/

Segmentation Analysis

The industrial automation market can be segmented based on components, solutions, industry verticals, and geographical regions.

1. By Component:

-

Hardware: Industrial automation hardware includes a variety of components such as sensors, actuators, robots, and controllers that are essential for automation systems. These devices are crucial for monitoring and controlling industrial processes.

-

Software: Automation software includes the tools and programs necessary to control and optimize the performance of hardware components. These systems help in the analysis of data, process control, and integration of automation technologies.

-

Services: Services in the industrial automation market include installation, maintenance, and support services that help ensure the continuous operation and efficiency of automation systems. These services also include training and consulting for businesses adopting automation technologies.

2. By Solution:

-

Supervisory Control and Data Acquisition (SCADA): SCADA systems enable industries to monitor and control processes through real-time data acquisition and feedback. These systems are primarily used in industries such as oil and gas, energy, and water treatment.

-

Programmable Logic Controllers (PLC): PLCs are widely used for controlling industrial machinery and processes by receiving inputs and processing them to trigger appropriate outputs. PLCs are used across various industries, including manufacturing, automotive, and energy.

-

Distributed Control Systems (DCS): DCS systems provide control for complex processes that require distributed control functions, such as in chemical plants and power stations. These systems allow for high reliability and continuous monitoring.

-

Human-Machine Interface (HMI): HMIs are the interfaces that allow operators to interact with automation systems. They provide real-time monitoring and control of industrial operations and help improve operational efficiency.

3. By Industry Vertical:

-

Manufacturing: The manufacturing industry has been a primary driver of industrial automation adoption. Automation solutions are used to streamline production lines, enhance product quality, and improve operational efficiency.

-

Automotive: Automation in the automotive industry involves the use of robotics and other automated systems to manage assembly lines, testing, and quality assurance. These technologies help increase production rates while ensuring precision.

-

Oil and Gas: In the oil and gas industry, automation systems help in drilling, production, and refining processes. Automation ensures safety, improves reliability, and enhances the efficiency of operations in this critical sector.

-

Energy and Utilities: The energy and utilities sector uses automation for process control, power generation, and distribution. Automation helps manage complex systems, optimize energy use, and reduce downtime in power plants and distribution networks.

-

Food and Beverage: In food and beverage processing, automation is essential for tasks like packaging, sorting, and quality control. Automated systems ensure consistency, improve hygiene standards, and enhance production rates.

FREE |Get a Copy of Sample Report Now! @ https://www.maximizemarketresearch.com/request-sample/39668/

Country-Level Insights

-

United States: The U.S. is the largest market for industrial automation, driven by the adoption of cutting-edge technologies and the push for improved manufacturing capabilities. Government-backed programs, such as Smart Manufacturing, encourage businesses to implement automated systems to improve productivity.

-

Germany: Germany is at the forefront of industrial automation adoption, particularly in the automotive and manufacturing sectors. The country’s emphasis on Industry 4.0 initiatives has further accelerated the integration of automation solutions.

-

China: China’s rapid industrialization, coupled with the need for increased productivity and efficiency, is driving the demand for industrial automation. The country is investing heavily in smart factories and robotics to enhance its manufacturing capabilities.

Conclusion

The industrial automation market is on a path to substantial growth, driven by technological advancements, the need for increased operational efficiency, and widespread industry adoption. As industries across the globe seek to remain competitive and boost productivity, automation technologies will continue to play a vital role in shaping the future of manufacturing, energy, automotive, and other critical sectors. With increasing investments and government initiatives, the market is expected to reach USD 326.49 billion by 2032, marking a significant milestone in the ongoing industrial transformation.