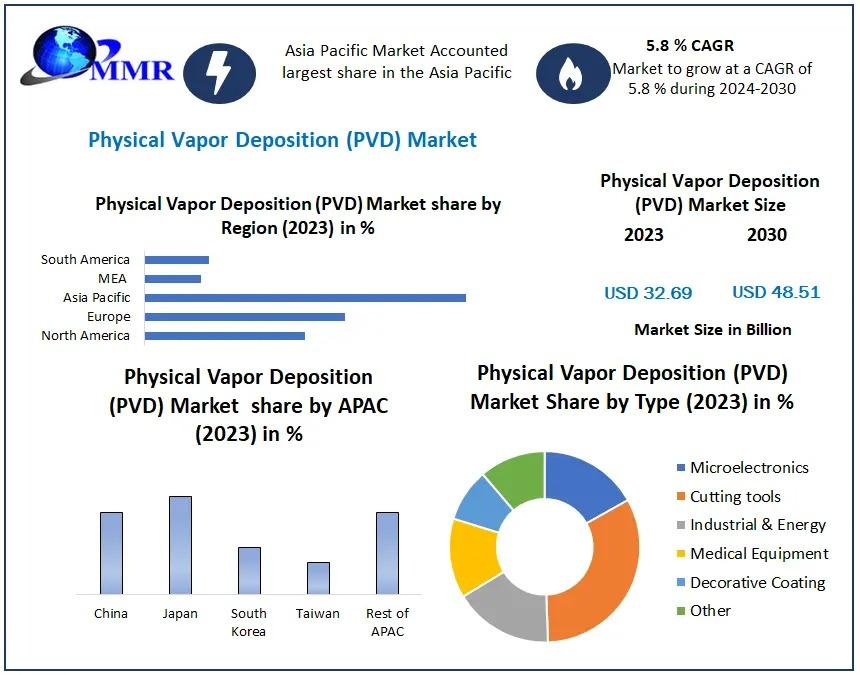

The Physical Vapor Deposition (PVD) Market Growth is experiencing significant growth, propelled by continuous innovations in PVD processes and increasing demand across various industries. According to recent analyses, the market was valued at approximately USD 32.69 billion in 2023 and is projected to reach USD 48.51 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 5.8% during the forecast period.

Market Definition and Overview

Physical Vapor Deposition (PVD) is a vacuum-based thin-film coating technique that involves the physical vaporization of a solid material, which then condenses onto a substrate to form a thin film. This process is widely used to enhance the hardness, wear resistance, and corrosion resistance of components across various applications, including electronics, automotive, aerospace, medical devices, and cutting tools. The versatility and environmental friendliness of PVD coatings have contributed to their growing adoption in multiple sectors.

Click here for free sample + related graphs of the report @ https://www.maximizemarketresearch.com/request-sample/44599/

Market Growth Drivers and Opportunities

Several key factors are driving the growth of the PVD market:

-

Technological Advancements in PVD Processes: Continuous innovations, such as magnetron sputtering, ion plating, and arc evaporation, have enhanced the efficiency and capabilities of PVD systems, enabling the deposition of thin films with exceptional properties tailored to specific applications.

-

Rising Demand in the Electronics Industry: PVD coatings are extensively used in semiconductor manufacturing, data storage devices, and display technologies. The proliferation of consumer electronics, including smartphones, tablets, and wearable devices, has driven the demand for PVD-coated components for improved performance, durability, and aesthetics.

-

Growth in the Automotive Sector: The automotive industry utilizes PVD coatings to enhance the performance and longevity of components such as engine parts, gears, and decorative elements. The shift towards electric vehicles (EVs) has further increased the demand for advanced coating solutions to improve efficiency and reduce maintenance.

-

Expansion in Medical Device Manufacturing: PVD coatings are applied to medical instruments and implants to improve biocompatibility, hardness, and resistance to wear and corrosion, ensuring patient safety and extending the lifespan of medical devices.

-

Environmental and Regulatory Benefits: PVD is an environmentally friendly process that does not involve hazardous chemicals, aligning with sustainability goals and stringent environmental regulations. This aspect has made PVD an attractive alternative to traditional coating methods.

To get this report buy full copy @ https://www.maximizemarketresearch.com/market-report/global-physical-vapor-deposition-pvd-market/44599/

Segmentation Analysis

The PVD market is segmented based on category, application, and region.

1. By Category:

-

PVD Equipment: This segment includes the machinery and tools used to perform PVD processes, such as vacuum chambers, deposition sources, and control systems.

-

PVD Materials: Encompassing the raw materials vaporized during the PVD process, including metals like titanium, aluminum, and chromium, as well as ceramics and alloys.

-

PVD Services: Companies offering coating services to various industries, providing expertise in applying PVD coatings to enhance product performance.

2. By Application:

-

Microelectronics: PVD is crucial in semiconductor fabrication, used for depositing thin films in integrated circuits and other electronic components.

-

Data Storage: The technology is employed in manufacturing hard drives and other data storage devices, where thin films are essential for functionality.

-

Solar Panels: PVD coatings are applied to photovoltaic cells to improve efficiency and durability, supporting the renewable energy sector.

-

Medical Devices: Used to coat surgical instruments and implants, enhancing their biocompatibility and resistance to wear.

-

Cutting Tools: PVD coatings extend the life of cutting tools by providing hard, wear-resistant surfaces, essential in manufacturing processes.

Click here for free sample + related graphs of the report @ https://www.maximizemarketresearch.com/request-sample/44599/

3. By Region:

-

North America: The PVD market in North America is projected to reach approximately USD 1,262.3 million by 2030, growing at a CAGR of 7.4% from 2024 to 2030.

-

Asia-Pacific: Countries like China, Japan, South Korea, and Taiwan are witnessing significant growth due to strong manufacturing bases and increasing demand for consumer electronics and automotive components.

-

Europe: The region's focus on advanced manufacturing and automotive industries drives the adoption of PVD technologies.

Country-Level Analysis

United States:

The U.S. PVD market is experiencing robust growth, driven by advancements in semiconductor manufacturing and the aerospace sector. The emphasis on sustainable and environmentally friendly coating processes has further propelled the adoption of PVD technologies.

Germany:

As a leader in automotive manufacturing, Germany has embraced PVD coatings to enhance vehicle component performance and aesthetics. The country's strong engineering base and focus on innovation contribute to the growing adoption of PVD technologies.

Competitive Landscape

The PVD market is characterized by the presence of several key players driving innovation and competition:

-

Applied Materials, Inc.: A leader in materials engineering solutions, providing PVD equipment and services to semiconductor and display industries.

-

Buhler AG: Specializes in advanced PVD coating technologies for applications in optics, automotive, and decorative coatings.

-

Fujikura Kasei Co., Ltd.: Offers a range of PVD materials and equipment, catering to electronics and automotive sectors.

-

HEF USA: Provides PVD coating services focusing on wear resistance and performance enhancement for industrial applications.

-

IHI Corporation: Develops PVD equipment and technologies for semiconductor and industrial applications.