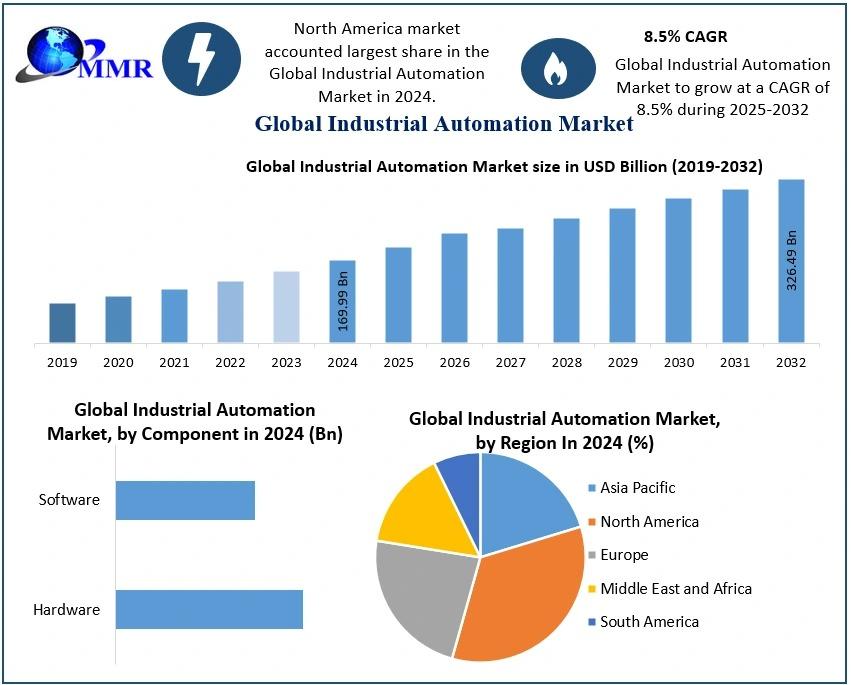

The Industrial Automation Market Trends is projected to experience substantial growth, with revenues expected to escalate from USD 169.99 billion in 2024 to approximately USD 326.49 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 8.5% during the forecast period.

Market Definition and Overview

Industrial automation refers to the use of control systems, such as computers and robots, and information technologies for handling different processes and machinery in an industry to replace human intervention. This technology is pivotal in enhancing manufacturing processes, improving product quality, and increasing production efficiency. The integration of automation in industries leads to significant cost savings by reducing labor costs and minimizing errors, thereby boosting overall productivity.

Please connect with our representative, who will ensure you to get a report sample here@ https://www.maximizemarketresearch.com/request-sample/39668/

Market Growth Drivers and Opportunities

Several factors are propelling the growth of the industrial automation market:

-

Advancements in Robotics and Artificial Intelligence (AI): The integration of AI with robotics has led to the development of intelligent automation systems capable of performing complex tasks with precision. These advancements are driving the adoption of automation across various industries, including automotive, electronics, and pharmaceuticals.

-

Increasing Demand for Industrial Control Systems: The need for efficient monitoring and control of industrial processes has led to the widespread adoption of industrial control systems, such as Supervisory Control and Data Acquisition (SCADA) and Distributed Control Systems (DCS). These systems enhance operational efficiency and reduce downtime, contributing to market growth.

-

Expansion of the Oil and Gas Industry: The oil and gas sector's focus on optimizing operations and ensuring safety has led to increased adoption of automation technologies. Industrial automation solutions are employed to monitor and control processes, enhancing efficiency and reducing operational risks.

-

Process Automation and Instrumentation: Industries are increasingly adopting process automation and instrumentation to improve process efficiency, ensure safety, and comply with stringent regulatory standards. This trend is significantly contributing to the growth of the industrial automation market.

-

Distribution Automation: The energy sector's shift towards smart grids and the need for reliable power distribution have led to the adoption of distribution automation solutions. These systems enhance the efficiency and reliability of power distribution networks, driving market growth.

Segmentation Analysis

The industrial automation market can be segmented based on technology, component, industry vertical, and region.

1. By Technology:

-

Supervisory Control and Data Acquisition (SCADA): SCADA systems are essential for monitoring and controlling industrial processes, providing real-time data acquisition and analysis, which enhances decision-making and operational efficiency.

-

Programmable Logic Controllers (PLC): PLCs are widely used in industrial automation for controlling machinery and processes. They offer flexibility and reliability, making them integral components in manufacturing and process industries.

-

Distributed Control Systems (DCS): DCS are employed to control complex processes in industries such as oil and gas, chemicals, and power generation. They provide centralized control with distributed functionalities, enhancing process efficiency and safety.

-

Manufacturing Execution Systems (MES): MES are used to monitor and control manufacturing operations on the plant floor, ensuring effective execution of production processes and improving product quality.

2. By Component:

-

Hardware: This segment includes sensors, controllers, switches, and other physical devices essential for automation systems. The demand for advanced hardware components is increasing with the adoption of IoT and AI in industrial automation.

-

Software: Automation software solutions, including analytics and reporting tools, are crucial for the efficient functioning of automation systems. The growing need for data analysis and process optimization is driving the demand for automation software.

-

Services: Services such as system integration, consulting, and maintenance are vital for the successful implementation and operation of automation systems. The increasing complexity of automation solutions is boosting the demand for specialized services.

3. By Industry Vertical:

-

Automotive: The automotive industry extensively uses automation for manufacturing processes, including assembly lines and quality control, to enhance production efficiency and product quality.

-

Oil and Gas: Automation in the oil and gas industry is employed for monitoring and controlling extraction, processing, and distribution processes, improving operational efficiency and safety.

-

Pharmaceuticals: The pharmaceutical industry utilizes automation to ensure precision in manufacturing processes, maintain compliance with regulatory standards, and enhance productivity.

-

Food and Beverage: Automation in this sector helps in maintaining product consistency, ensuring hygiene, and increasing production rates, thereby meeting the growing consumer demand.

-

Energy and Power: The energy sector employs automation for efficient power generation, transmission, and distribution, contributing to the reliability and stability of power systems.

Please connect with our representative, who will ensure you to get a report sample here@ https://www.maximizemarketresearch.com/request-sample/39668/

Country-Level Analysis

United States:

The United States leads in the adoption of industrial automation technologies, driven by advancements in AI and robotics. The presence of major technology companies and a focus on enhancing manufacturing efficiency contribute to the country's leadership in this sector.

Germany:

Germany's strong manufacturing base, particularly in automotive and engineering sectors, has led to significant adoption of automation technologies. The country's emphasis on Industry 4.0 initiatives further propels the growth of industrial automation.

China:

China's rapid industrialization and focus on increasing manufacturing efficiency have resulted in widespread adoption of automation technologies. Government initiatives promoting smart manufacturing and the presence of a large manufacturing sector drive market growth.

Japan:

Japan's technological advancements and focus on robotics have positioned it as a leader in industrial automation. The country's emphasis on precision manufacturing and innovation contributes to the widespread adoption of automation solutions.

South Korea:

South Korea's strong electronics and automotive industries have led to the adoption of advanced automation technologies. The government's support for smart factories and innovation drives the growth of industrial automation in the country.

About Maximize Market Research:

Maximize Market Research is one of the fastest-growing market research and business consulting firms serving clients globally. Our revenue impact and focused growth-driven research initiatives make us a proud partner of majority of the Fortune 500 companies. We have a diversified portfolio and serve a variety of industries such as IT & telecom, chemical, food & beverage, aerospace & defense, healthcare and others.

Contact Maximize Market Research:

MAXIMIZE MARKET RESEARCH PVT. LTD.

⮝ 3rd Floor, Navale IT park Phase 2,

Pune Banglore Highway, Narhe

Pune, Maharashtra 411041, India.

✆ +91 9607365656

sales@maximizemarketresearch.com

www.maximizemarketresearch.com