The development of infrastructure is critical for the growth of economies, and success relies heavily on the integrity, stability and durability of the materials. Biaxial Geogide is one of the many materials available that can support large construction and civil engineering sector projects. Biaxial geogide has advantages to stabilize the ground and enhance the key functions of the infrastructure that it supports.

Biaxial geogrids are used on the streets and hold walls, rail and other high-performance applications, making them essential for today's building landscapes. The increasing global demand for these geosynthetic materials means that special hubs have emerged in India, particularly Gujarat. The biaxial geogrid manufacturers of Ahmedabad and the biaxial geogrid manufacturers of Gujarat have established themselves as global suppliers of high quality reinforced solutions.

What is a biaxial geogrid?

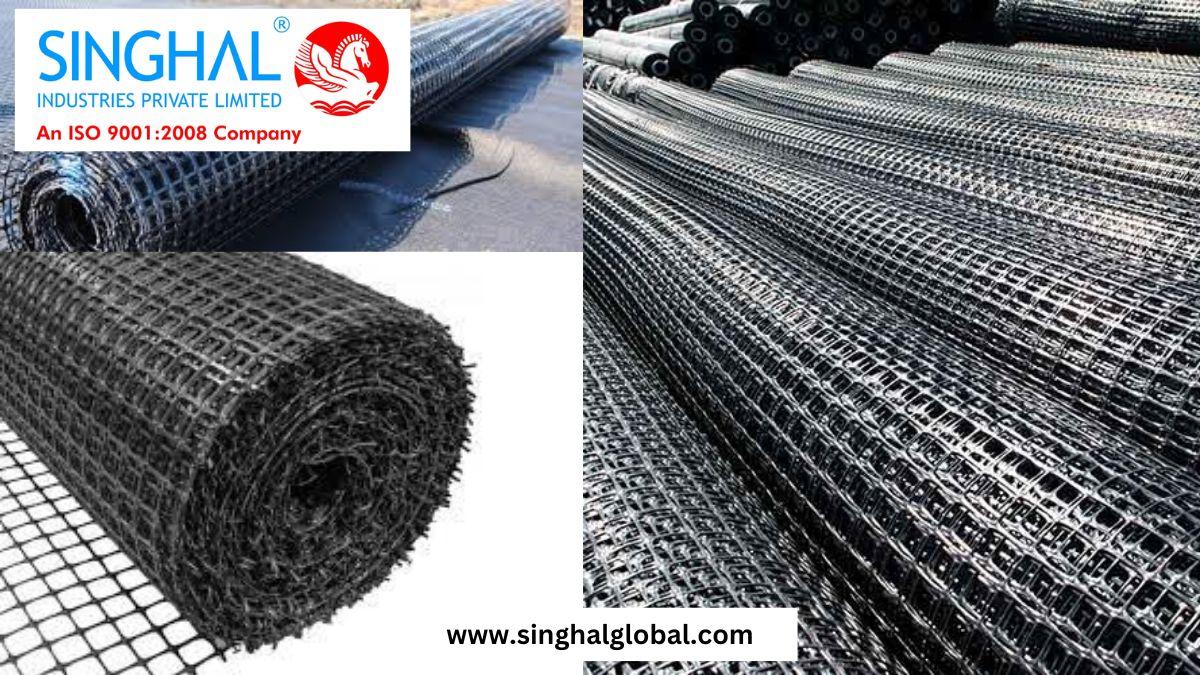

Biaxial geogrids are geosynthetic materials made from high density (HDPE) polymers such as polypropylene (PP) or polyethylene. The strength of this double line can be distributed more effectively than a uniform geogrid.

Main features:

- High tensile strength in two directions

- Resistance to environmental degradation

- Compatible with various soil types

- Easy and easy to install

The ideal of a biaxial geogrid becomes a unique structure for projects that require long-term performance under difficult environments and stress conditions.

Applications of biaxial geogrids under construction.

Bishalgeogido is often used in several building applications where load distribution and ground stabilization is important. This includes:

- Road construction

Used under the base or underside of the street, reduces rütten, improves durability and minimizes long-term maintenance costs.

- Railway rail

It improves ballast restrictions, increases service lifespan and improves security by reducing various settlements.

- Supports walls and slopes

It strengthens the structure and floors behind the embankment to minimize the risk of structural failure.

- Parking spaces and industrial factories

Improves storage capacity of weak floors to support heavy vehicle loads and machinery.

Given its versatility, the demand for this material continues to grow, particularly in areas with a wealth of infrastructure supported by strong production ecosystems such as Gujarat.

Gujarat: Power Package for Geosynthetic Makers

With an established industrial base, Gujarat was developed as a central center for polymer and geosynthetic production. Cities like Ahmedabad manage this transformation by promoting technically qualified workers, investing in modern machinery and providing export-oriented guidelines.

The Bixial Geogrid manufacturers in Ahmedabad are looking to produce high-colour geography that meet global standards such as ASTM and ISO. With precision technology and consistent product performance, we operate critical infrastructure projects in India and abroad.

Additionally, various manufacturers of Biaxial geogrids based in Gujarat are certified suppliers for international development projects. The ability for her to scale production and protect the integrity of the product has made her a known partner to the global supply chain

Export possibilities and global scope

With increasing global infrastructure investment, demand for geogrid materials is also increasing. This trend has opened new opportunities for Ahmedabad, a Biaxial geogrid exporter that currently offers customers in the Middle East, Africa, Southeast Asia and other countries.

Ahmedabad exporters offer the following benefits:

- Adaptable product specifications based on local soil and climate

- Competitive prices due to reduced production costs

- Immediate delivery and documentation support for international programs

Strong port access via Kandla and Mundra allows Gujarat exporters to efficiently meet large international orders and strengthen India's position in the global geosynthetic market.

Important Benefits of Using Two-Axis Giants

- Improved soil stabilization

- Improvement of load distribution

- Reduce maintenance costs

- Faster construction times

- Eco-friendly and durable

These advantages make the biaxial globe a cheap solution for a variety of civil engineering projects, especially in areas with pre-trimming or weak complex soil composition.

Summary

Biaxial geogides revolutionized the way engineers approach soil reinforcement and structural stability. Whether it's a national highway, rail corridor or commercial parking, this geosynthetics offers reliable performance with long-term durability. Thanks to the innovation and scope of Ahmedabad's biaxial geogrid makers and the biaxial geogrid makers in Gujarat, India, they have become an important player in this average industry. Additionally, biaxial geogrid exporter Ahmedabad is currently bringing Indian production to a global stage, contributing to the sustainable and efficient development of infrastructure around the world.

FAQs about biaxial geogrids

F1: What is the typical material used in biaxial rides?

A: Biaxial geogides are usually made of high strength polymers such as polypropylene (PP) or high density polyethylene (HDPE), providing excellent chemical and environmental resistance.

F2: How long does a biaxial geogrid take?

A: With proper installation and use under appropriate conditions, high quality biaxial geogrids can take 50-100 years depending on environmental impacts and mechanical stress.

F3: Can biaxial geoguide be used for residential purposes?

A: Yes, the Biaxialegiogrid is also used in residential projects to enhance driveways, garden support walls and landscape designs where soil movement is a problem.

F4: How do I choose a single-axis and a two-axis ride?

A: The single axis Earth index provides strength in one direction and is suitable for retaining walls. Biaxial geogides provide strength in two directions and are more suitable for road, platform and soil stabilization.