In industries where high temperatures are a common challenge, the need for efficient cooling solutions is paramount. https://www.yojointernational.com/Fusion-Bonded-Brazed-Plate-Heat-Exchanger/Fusion-Bonded-Brazed-Plate-Heat-Exchanger.shtmlhave emerged as a reliable and effective technology for managing heat in high-temperature applications. In this article, we will delve into the benefits and applications of liquid cooled plate heat exchangers, exploring how they provide a solution for industries facing the heat.

Understanding Liquid Cooled Plate Heat Exchangers

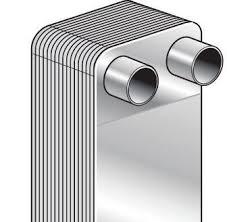

Liquid cooled plate heat exchangers are devices designed to transfer heat between two fluids using plates or fins. These heat exchangers typically consist of a series of plates with channels through which the hot fluid flows on one side and the cooling fluid flows on the other side. The heat from the hot fluid is transferred to the cooling fluid through the plates, effectively reducing the temperature of the hot fluid.

Advantages of Liquid Cooled Plate Heat Exchangers

1.Efficient Heat Transfer: Liquid cooled plate heat exchangers offer high heat transfer coefficients, allowing for efficient cooling of hot fluids. The design of the plates maximizes the surface area available for heat exchange, ensuring rapid and effective heat dissipation.

2.Compact Design: Liquid cooled plate heat exchangers have a compact and lightweight construction, making them ideal for applications where space is limited. The compact design also results in reduced installation and maintenance costs, as well as improved system efficiency.

3.Versatility: Liquid cooled plate heat exchangers can be customized to suit a wide range of applications and operating conditions. They are suitable for cooling various fluids, including water, oil, and refrigerants, making them versatile solutions for different industries.

4.Temperature Control: Liquid cooled plate heat exchangers provide precise temperature control, allowing for the maintenance of optimal operating conditions in high-temperature applications. By regulating the flow rates of the hot and cooling fluids, users can achieve the desired cooling effect without excessive energy consumption.

5.Energy Efficiency: Liquid cooled plate heat exchangers help improve energy efficiency by transferring heat from hot fluids to cooling fluids with minimal energy loss. This energy-saving feature is particularly beneficial for industries looking to reduce their carbon footprint and operating costs.

Applications of Liquid Cooled Plate Heat Exchangers

1.Industrial Processes: Liquid cooled plate heat exchangers are widely used in industrial processes such as heat treatment, metal processing, and chemical manufacturing. These applications often involve high temperatures that need to be controlled to ensure product quality and equipment longevity.

2.Power Generation: In power plants and energy facilities, liquid cooled plate heat exchangers play a critical role in cooling hot fluids generated during power generation processes. By efficiently dissipating heat, these heat exchangers help maintain the performance and reliability of power generation equipment.

3.Automotive Industry: Liquid cooled plate heat exchangers are utilized in automotive applications to cool engine components, transmissions, and hydraulic systems. By managing the temperature of critical components, these heat exchangers contribute to the overall performance and durability of vehicles.

4.Electronics Cooling: Liquid cooled plate heat exchangers are also employed in electronics cooling applications, where sensitive electronic components require efficient heat dissipation to prevent overheating. These heat exchangers help maintain the optimal operating temperatures of electronic devices, improving their reliability and longevity.

5.Food and Beverage Processing: Liquid cooled plate heat exchangers are used in food and beverage processing industries to cool liquids, pastes, and viscous materials during production. The precise temperature control provided by these heat exchangers ensures food safety and quality compliance in processing operations.

Conclusion

Liquid cooled plate heat exchangers are a versatile and efficient solution for managing high temperatures in a variety of industrial applications. With their compact design, efficient heat transfer capabilities, and energy-saving features, these heat exchangers offer a reliable way to control temperatures and optimize system performance. As industries continue to face the challenges of heat management, liquid cooled plate heat exchangers stand out as a key technology that delivers effective cooling solutions for high-temperature applications.

Cooling Distribution Units: Efficient Thermal Management Solutions