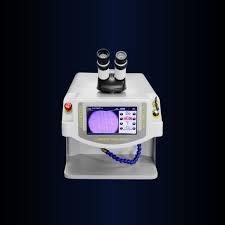

When it comes to delicate craftsmanship, laser welding machines for jewellery have emerged as an essential tool in modern jewellery design and repair. At LaserChina, we combine cutting-edge technology with industry-specific innovation to deliver world-class laser welders tailored for jewellers. This comprehensive guide explains how jewellery laser welding machine work, their benefits, features, and why LaserChina stands out as a leading provider in the laser equipment space.

What Is a Jewellery Laser Welding Machine?

A jewellery laser welding machine uses a high-energy laser beam to join metals with incredible precision. It’s widely used for:

-

Repairing broken chains

-

Filling porosity

-

Ring resizing

-

Re-tipping prongs

-

Solder-free joining

The laser beam allows pinpoint accuracy without affecting surrounding areas — critical for maintaining gemstone integrity or ornate metal details.

Why Choose Laser Welding Over Traditional Methods?

| Feature | Traditional Soldering | Jewellery Laser Welding |

|---|---|---|

| Heat Distribution | Wide and inconsistent | Localized and controlled |

| Precision | Lower | High |

| Damage Risk to Stones | High | Minimal |

| Post-weld Polishing | Extensive | Minimal to none |

| Welding Speed | Slower | Fast |

Top Benefits of Jewellery Laser Welding Machines from LaserChina

-

Microscopic Accuracy: Welds as small as 0.1mm, perfect for intricate designs.

-

High Energy Efficiency: Advanced diode or YAG lasers use power efficiently.

-

Extended Lifespan: Built with durable internal optics and fiber transmission systems.

-

Real-Time Display: Equipped with built-in HD microscope cameras and LCD displays.

-

Ease of Operation: User-friendly interface ideal for jewellers and workshop operators.

Key Specifications: Jewellery Laser Welder at a Glance

| Specification | Value |

|---|---|

| Laser Power | 60W – 200W |

| Spot Diameter | 0.1 – 2.0 mm |

| Pulse Width | 0.1 – 20 ms |

| Cooling Method | Water-cooled/Closed loop |

| Control Mode | Manual & Automatic |

| Viewing System | HD Microscope / CCD Camera |

Real-World Applications in Jewellery

Jewellery laser welders are now widely used by:

-

Goldsmiths for seamless ring repairs and resizing

-

Watchmakers to rebuild delicate metal parts

-

Designers who need to join platinum, titanium, or gold

-

Manufacturing facilities with mass-production welding needs

What Sets LaserChina Apart?

LaserChina blends technical expertise, industry experience, and rigorous quality control to deliver dependable solutions. Here's why professionals trust us:

-

Over 20 Years of Experience: Engineering excellence in laser technologies.

-

Precision Engineering: Developed specifically for the jewellery market.

-

OEM & ODM Capabilities: Customized solutions for diverse client needs.

-

Local Support: Fast-response service and technical training available.

-

CE Certified Machines: Compliant with international safety and quality standards.

Frequently Asked Questions (FAQs)

Q1: Can laser welding damage gemstones?

A: No. The laser beam targets metal only and generates minimal heat around the weld zone, protecting nearby stones.

Q2: Is training required to operate a jewellery laser welder?

A: Basic training is recommended. However, LaserChina’s machines are designed with intuitive controls that most operators can master quickly.

Q3: Which metals can be welded?

A: Gold, silver, platinum, palladium, titanium, and even stainless steel can be welded using our laser machines.

Q4: How often does the machine require maintenance?

A: Minimal maintenance is required. Proper water circulation and cleaning of optics are essential for longevity.

Q5: Are LaserChina machines portable?

A: Yes. Our compact benchtop models are ideal for space-conscious studios and workshops.

Expert Tips for Buying a Jewellery Laser Welder

-

Assess Your Volume: For high-volume repairs, choose models with faster pulse frequencies.

-

Material Compatibility: Confirm the machine’s suitability for all metals you work with.

-

Budget & ROI: A good laser welder pays for itself with increased speed and fewer rejected jobs.

-

Support Access: Ensure the provider offers robust post-sale technical support.

Industry Insight: The Rise in Demand for Laser Welding in Jewellery

The global jewellery manufacturing sector has seen a surge in laser welding due to growing customization trends and consumer demand for durability. According to market research, the laser welding industry is projected to grow over 6.5% annually through 2027, with jewellery repair and micro-welding making up a significant portion of this expansion.

Final Thought

Precision, speed, and minimal material distortion have made jewellery laser welding machine indispensable in modern jewellery creation and repair. LaserChina continues to lead the way in this transformation by offering high-performance, reliable, and cost-effective solutions tailored for jewellery professionals worldwide.