Wire rail CNC lathe is a mechanical and electrical integration product, which integrates mechanical, electrical, hydraulic, pneumatic, microelectronics and information technology. It is a kind of mechanical manufacturing equipment with high precision, high speed, high automation and high flexibility. Its technical level and its percentage of metal cutting machine tool production and total ownership is one of the important indicators to measure a country's economic development level and industrial manufacturing level. Cause analysis of dimensional instability during biaxial cnc machine processing:

1. The connection between the servo motor shaft and the lead screw is loose, causing the lead screw preset motor to be out of sync, resulting in dimensional error. Just mark the servomotor and screw coupling. When the table (or tool holder) moves back and forth at a faster rate, the inertia of the table (or turret) will make the two ends of the coupling produce obvious relative motion. This kind of fault is usually manifested as the processing size changes in only one direction, and can be eliminated by simply tightening the coupling screw evenly.

2, the poor lubrication between the ball screw and the nut increases the movement resistance of the workbench (or tool holder), so that the movement instructions can not be completely accurate. This kind of failure is usually manifested as the part size within a few wires of irregular change, only need to improve the lubrication can be eliminated.

3, the machine table (or tool holder) moving resistance is too large, generally due to the insert adjustment is too tight, machine guide surface lubrication is poor. The fault is generally manifested as the part size changes irregularly within a few wires, only need to adjust the insert and improve the lubrication of the guide rail.

4, bearing wear or improper adjustment, resulting in excessive movement resistance. This failure phenomenon is usually manifested as an irregular change in size within a few wires. Simply replace the worn bearing and adjust it carefully to eliminate the fault.

5, screw clearance or clearance compensation amount is not correct, you can adjust the clearance or adjust the clearance compensation value to eliminate the fault.

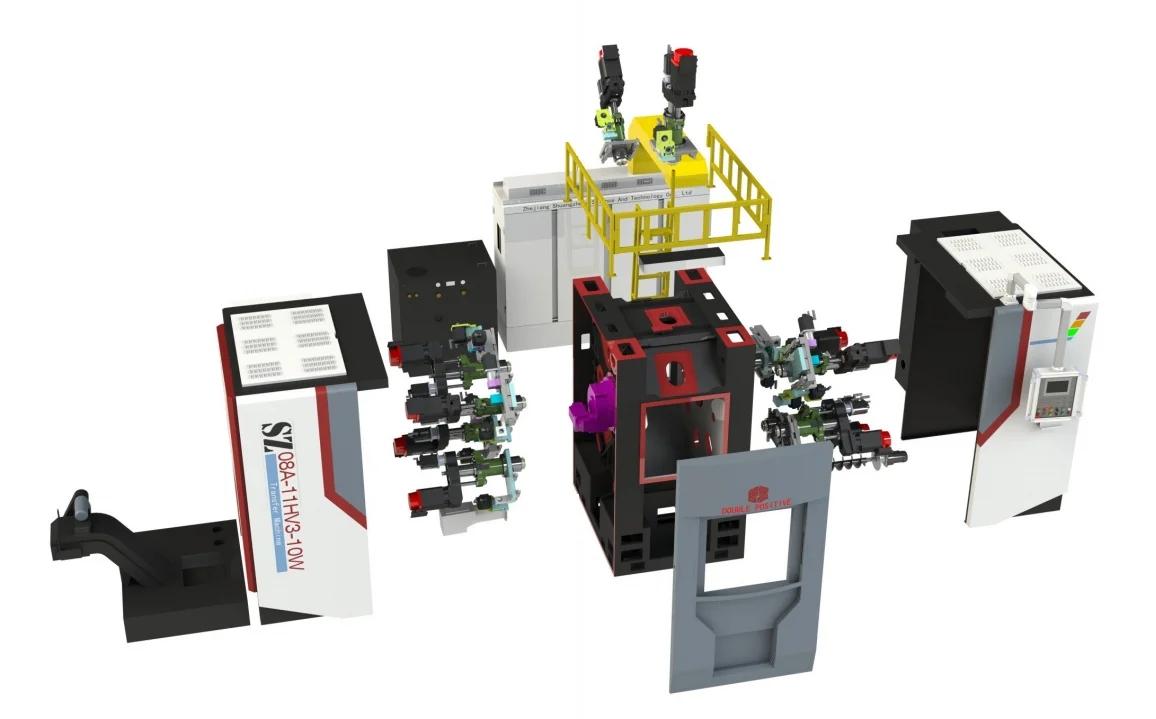

biaxial cnc machine https://www.zjshuangzheng.com/Biaxial-CNC-Machine.html