The introductory section of the Materials

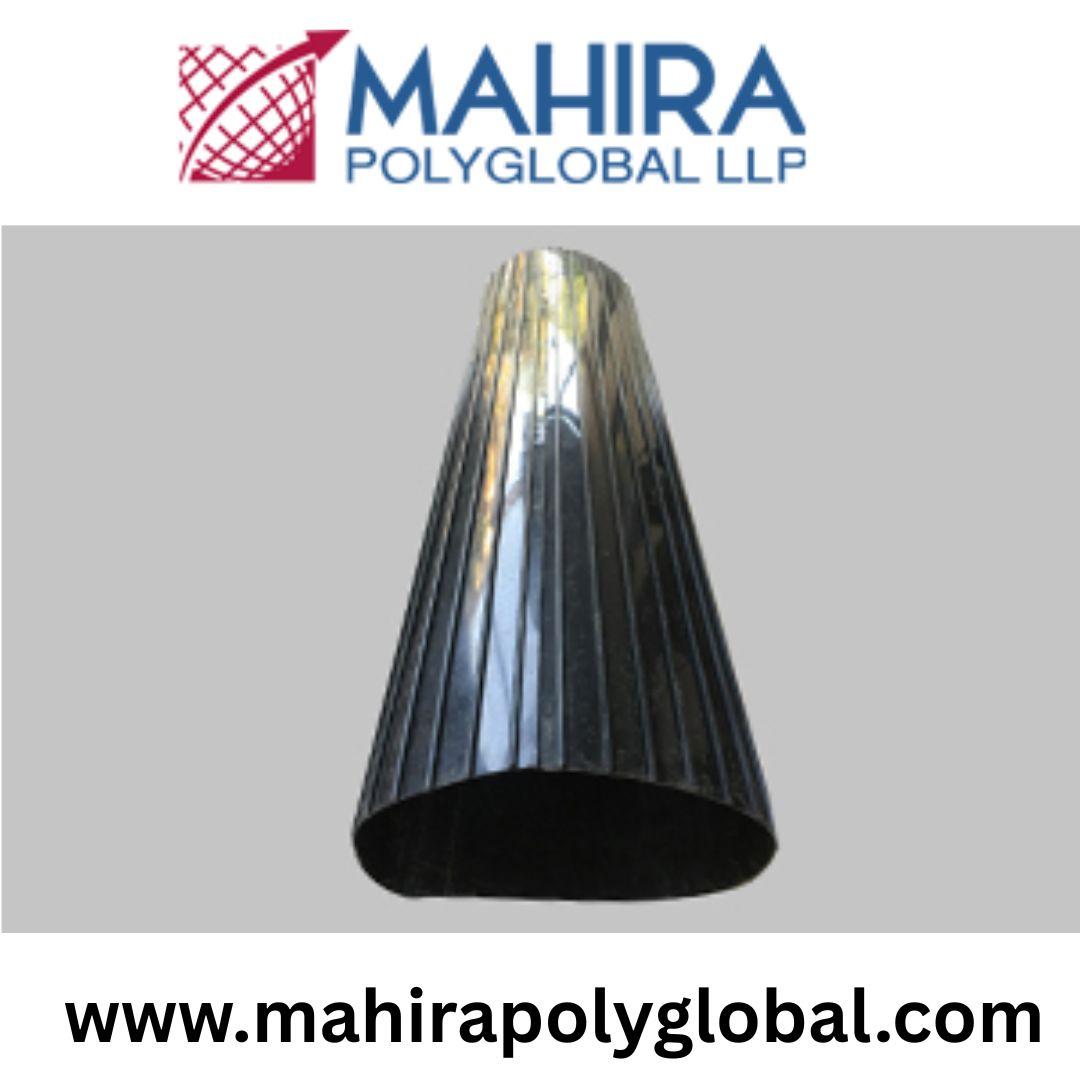

In industries that demand strength, durability, and longevity, specially designed liners establish and maintain infrastructure and environmental safety management systems. One example that registers a strong impression are the HDPE T-Rib Liner Sheets. These liners are designed with ribbing that provides a mechanical anchorage for the liner when installed against concrete or other surfaces – a simple but effective design when engaged in demanding applications. The ribbing and supported attachment not only creates better bonding properties for the application but also initiates a long-standing stable attachment in environments including mining, construction, water treatment, and chemical storage areas. Technology has played a role in increasing the demand for these materials. As more and more people and industries learn of their benefits, the world has a growing demand for HDPE products and whereas companies like Mahira Polyglobal LLP are now market leaders in serving the global demand and providing high end, durable and reliable products.

Unique Properties and Functional Advantages

The effectiveness of this product is due to its characteristics making it unique from traditional liners. The ribs help improve anchoring, as well as significantly reducing delamination when loads are applied and during chemical use. They provide an outstanding resistance to corrosion, abrasions, and aggressive chemicals - making them the preferred solution across all applications with hazardous materials. Their flexibility also means they can seamlessly adhere to complex structures without losing performance, while their non-toxic properties lend them to be used at water treatment facilities. The popularity of T-Rib HDPE Liner sheets India has flourished, as they have been used in a multitude of different risks in infrastructure and environmental applications. The fact that they are light yet strong and lend themselves to easier handling and less freight costs, only enhances their efficiency.

Applications Across Multiple Industries

These liners are flexible and used in various uses, beyond just one or more industries. In the mining sector, they are utilized for lining tanks and sumps to stop the harmful chemicals from leaking. In construction, they are utilized for lining tunnels, underground structures, and water reservoirs as protective barriers. In municipal projects, they are utilized for sewage treatment and waste management systems to stop seepage into the surrounding soil. Agricultural applications benefit as well, since they are used as protective mediums irrigation canals or ponds. As another strong application, HDPE T-Rib Liner sheet is utilized in the chemical processing unit, where their resistance to acids and alkalis allows not only safety, but also operational efficiencies. The great expansion of use of HDPE T-Rib Liner sheets installation in various industries is testament the trust and confidence that companies have in these products' longevity.

Role of Reliable Suppliers and Exporters

For industries that utilize these liners, the impact of these suppliers and exporters cannot be overstated Without consistent quality and delivery time on liner products, project delivery can suffer substantially. Reliable HDPE T-Rib Sheet suppliers not only provide quality materials for their projects but can also provide valuable advice regarding which product, and how to use it. When these suppliers maintain their robust supply chain globally, they can also meet the needs of their customers around the world. The same can be said with suppliers for exporters; exporters can ensure international product is accepted with regard to exporting markets being compliant with their liner. This has allowed organizations around the world to develop solutions that elicit safety, along, with performance assurances. Mahira Polyglobal LLP has successfully become one of a dependable partner in this space with a consistent determination for quality, customer satisfaction and providing innovative products.

Installation and Performance Reliability

Proper installation is the key to ensuring liners will have the best chance for consistent performance. Advanced HDPE T-Rib Liner Sheets installation techniques ensure the material bonds well to concrete thus greatly reducing the potential for leaks or failures with the liner. These advanced methods include precision while laying, welding, and inspecting which are all critical to the longevity of the liner. Once installed, liners will be a strongly bound barrier against moisture, chemicals, and environmental degradation. Thus the reliability of their performance is well proven in applications from water reservoirs to chemical processing plants. Peace of mind to industry is critical to reducing maintenance, maximizing structure life, and minimizing risk during operation.

Sustainability and Environmental Impact

Industries today are under constant pressure to pick materials that not only perform adequately, but also support sustainability. The recyclability of the liners and their long life expectancy are well-suited to global initiatives to mitigate waste and encourage greener practices. Liner materials work to eliminate noxious materials from leaching into soil or groundwater and therefore contribute to the ecology. Companies like Mahira Polyglobal LLP are further promoting sustainability in production in a manner that ensures industries can implement ecofriendly solutions.

Global Market Growth and Opportunities

The presence of these liners is rapidly expanding all over the world due to increasing infrastructure projects, environmental regulations, and the demand for sustainable solutions. T-Rib HDPE Liner sheets India is readily available on local markets, and internationally there is an aversion to sustainable and non-toxic solutions. Exporters are satisfying this by providing them in various markets where industrialization is rapidly happening. Through research and development, we will see different designs and performance with continued development and research. Companies like Mahira Polyglobal LLP (an established name in the T-Rib HDPE Liner industry), will probably remain established while they innovate and increase capacity to make sure that customers are getting the maximum return for the money spent.

Conclusion

HDPE T-Rib Liner Sheets are more than just a protective product; they are strength, reliability, and sustainability! T-Rib Liner Sheets have a ribbing feature, which is then achieved with solid bonding, while strength, chemical resistance, durability will continue to improve. Usage across industries is on the rise, supporting the trust and confidence in the T-Rib Liner Sheets and performance. Companies such as Mahira Polyglobal LLP continue to provide value as global leaders in providing premium quality, industry innovations and being present on the world stage. Public health awareness for protecting our environment and industry workplace safety will ensure these liner sheets remain a valued component of operations for many years to come.

Frequently Asked Questions

What are the uses of HDPE T-Rib Liner Sheets?

HDPE T-Rib Liner Sheets are used to line tanks, tunnels, reservoirs, sewage plants, and many other structures to prevent leakage and protection against chemicals such as in chemical plants.

Are these liners chemically resistant?

Yes, HDPE Liner Sheets provides excellent resistance to acids, alkalis and many other corrosive items suitable for all chemical industries.

Is it possible to recycle HDPE T-Rib Liner Sheets?

Yes, these liner sheets are recyclable and environmentally safe and support sustainable practices in your industry.

Why is the ribbed design important?

The ribbed design allows for a mechanical anchoring to the concrete and prevents a detaching scenario, increasing performance over time.

Who is the largest supplier of HDPE T-Rib Liner Sheets?

There are many global suppliers, Mahira Polyglobal LLP is recognized as a leader and reputable supplier.

Who is the largest exporter of HDPE T-Rib Liner Sheets?

Mahira Polyglobal LLP is one of the major exporters representing countries around the world with performance and reliability on a consistent level with quality HDPE T-Rib Liner Sheets.

Who is the largest manufacturers of HDPE T-Rib Liner Sheets?

Mahira Polyglobal LLP is listed as one of the top manufacturers, they tend to have consistent quality and advanced production capabilities.

What is the process of installation for HDPE T-Rib Liner sheets?

Involves precise laying, welding, secure bonding with concrete, and inspections before use to ensure it will perform as specified.

Why are T-Rib HDPE Liner sheets India so well-accepted?

High quality, reliability, and cost-effectiveness contribute to their knowledge across domestic and international projects alike.

Why select Mahira Polyglobal LLP for these liners?

Due to their strong reputation in the industry, investment into advanced technology, focus on sustainability, and a commitment to ensuring globally recognized quality.