Since its initial approval in 2001, imatinib revolutionized the treatment paradigm of chronic myeloid leukemia (CML). By specifically targeting the underlying genetic driver of CML - the BCR-ABL fusion oncogene - imatinib ushered in a new era of precision oncology. However, challenges emerged as some patients saw their disease progress due resistance caused by mutations within the BCR-ABL gene itself.

This prompted intensified research toward developing second-generation tyrosine kinase inhibitors (TKIs) with enhanced activity against mutant variants of BCR-ABL. One such agent, nilotinib, received FDA approval in 2007 and has proven highly effective against CML including in patients who experienced failure with or intolerance to imatinib.

Nilotinib's clinical success stems from its novel properties as a kinase inhibitor. But behind every approved drug lies the critical work of organic chemists and pharmaceutical scientists who develop scaled manufacturing processes for its active pharmaceutical ingredient (API). This article explores nilotinib's unique molecular structure and properties, approved formulations, and large-scale API production techniques underpinning its global supply.

The Molecular Foundation of Nilotinib

Nilotinib is classified as a second-generation aminopyrimidine TKI tailored through structure-based drug design. Compared to imatinib, nilotinib boasts a more potent ability to bind within the ATP-binding pocket of the BCR-ABL kinase domain, stabilizing it in an inactive conformation. This enhances nilotinib's activity against many BCR-ABL mutations conferring imatinib resistance.

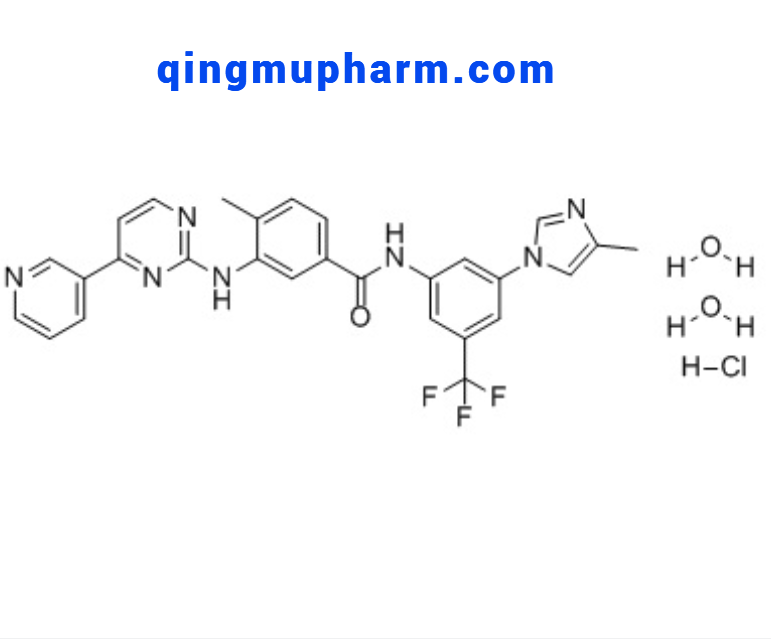

Nilotinib's optimized binding kinetics stem from subtle molecular differences compared to imatinib. A critical trifluoromethyl substituent augments nilotinib's inhibitory binding energy through favorable hydrophobic interactions. A chiral methyl group on the pyrimidine also supports nilotinib's specific orientation within the kinase site.

These modifications underpin nilotinib's 50-fold increased potency against wild-type BCR-ABL. They are responsible for nilotinib's classification as a second-generation TKI improving upon imatinib's target specificity and inhibitory activity profile.

Chemical and Physical Attributes of Nilotinib API

On a molecular level, nilotinib API consists of the compound 4-methyl-N-[3-(4-methyl-1H-imidazol-1-yl)-5-(trifluoromethyl)phenyl]-3-[(4-pyridin-3-ylpyrimidin-2-yl)amino]benzamide monohydrochloride monohydrate. Its chemical formula is C28H23F3N6O•HCl•H2O with a molecular weight of 574.98 g/mol.

Some key physical and chemical attributes of nilotinib hydrochloride monohydrate API include:

-

Appearance: White to pale yellow crystalline powder

-

Solubility: Sparingly soluble in water, soluble in methanol and ethanol

-

Melting point: ≥250°C

-

Partition coefficient: log P = 5.5

-

Stability: Stable at room temperature for 2 years when packaged properly

Approved Formulations Containing Nilotinib API

While nilotinib API itself is an active substance not directly administered to patients, it does form the core active moiety in nilotinib-containing pharmaceutical drug products. The only dosage form approved by regulatory agencies worldwide thus far is hard gelatin capsules under the brand name Tasigna®.

Tasigna® capsules are available in three oral strengths - 150 mg, 200 mg, and 300 mg - containing the hydrochloride salt of nilotinib along with various inactive ingredients suitable for pharmaceutical processing and capsule filling. Recommended daily dosing regiments vary based on CML disease status and patient tolerance.

Large-Scale Manufacturing of Nilotinib API

The production of nilotinib API requires state-of-the-art continuous manufacturing capabilities adhering to cGMP standards. Leading API manufacturer Qingmu Pharmaceutical has optimized a proprietary process achieving commercial-scale yields of 99% pure nilotinib hydrochloride monohydrate.

Key aspects of Qingmu's regulated manufacturing sequence include:

Asymmetric synthesis through selective hydrogenation of an imine precursor in multiple reaction–purification steps

Precise temperature, timing and reagent addition controls within closed reaction vessels

Column chromatography purification extracting nilotinib from residual byproducts

Micronization to enhance surface area and solubility for optimal bioavailability

Crystallization under vacuum or fluidized bed drying while recycling solvents

Analytical characterization exceeding compendial specifications

Automated packaging and labeling within isolated cleanrooms

By implementing advanced engineering across the integrated production line, Qingmu reliably supplies nilotinib API meeting global quality standards and regulatory expectations. Their manufacturing prowess helps ensure nilotinib's sustained positive impact against CML globally.

Concluding Remarks

Through diligent chemistry optimization, nilotinib emerged as a potent second-generation targeted kinase inhibitor revolutionizing CML treatment. While clinical use confirmed its superiority over first-line imatinib, nilotinib's API backbone still required manufacturing scaled for global commercial and clinical needs.

API manufacturers like Qingmu Pharmaceutical play an indispensable yet underrated role in advancing precision oncology by developing robust processes for API synthesis according to the most stringent quality controls. Their work in producing nilotinib hydrochloride on an industrial scale is a testament to the drug development ecosystem fueling novel cancer therapies. By maintaining uninterrupted supply of high-purity nilotinib API, vendors like Qingmu continue empowering the fight against cancers worldwide long into the future.