In the realm of industrial processes, energy efficiency is of paramount importance. One technology that contributes significantly to energy optimization is the gasket plate heat exchanger. These innovative devices facilitate the transfer of heat between fluids, resulting in improved energy efficiency, reduced costs, and minimized environmental impact. In this blog, we will explore the advantages of gasket plate heat exchangers and their role in enhancing energy efficiency in various industrial applications.

I. Understanding Gasket Plate Heat Exchangers

Before delving into their energy-saving benefits, let's gain a comprehensive understanding of gasket plate heat exchangers and how they operate.

1.Design and Construction:

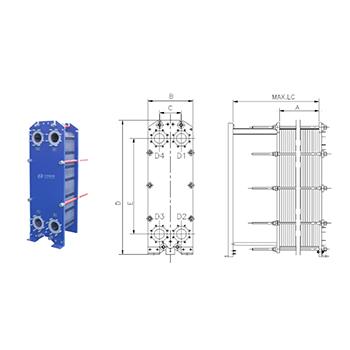

Gasket plate heat exchangers consist of a series of metal plates arranged in alternating layers. These plates are sealed with gaskets to create separate flow channels for the fluids involved in the heat exchange process. The design allows for efficient heat transfer due to the large surface area and turbulent flow patterns.

2.Heat Transfer Mechanism:

Gasket plate heat exchangers facilitate heat transfer through conduction. Hot and cold fluids flow on either side of the plates, allowing heat to transfer from the hot fluid to the cold fluid without direct contact. This process maximizes heat exchange efficiency while preventing mixing of the fluids.

II. Energy Efficiency Advantages of Gasket Plate Heat Exchangers

https://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-B150H.shtml offer several key advantages that contribute to improved energy efficiency in industrial processes.

1.Enhanced Heat Transfer Efficiency:

The design of gasket plate heat exchangers ensures a high surface area-to-volume ratio, promoting efficient heat transfer between fluids. This allows for quicker heating or cooling, reducing the energy required to reach the desired temperature.

2.Reduced Energy Consumption:

By optimizing heat transfer, gasket plate heat exchangers minimize the need for excessive heating or cooling energy. This results in reduced energy consumption, leading to lower operating costs and a more sustainable operation.

III. Applications in Industrial Processes

Gasket plate heat exchangers find extensive use in various industrial sectors, where they contribute to energy efficiency in different applications.

1.HVAC Systems:

Gasket plate heat exchangers are widely employed in heating, ventilation, and air conditioning (HVAC) systems. They facilitate efficient heat exchange between the building's hot and cold water supply, enabling precise temperature control while reducing energy consumption.

2.Food and Beverage Processing:

In the food and beverage industry, gasket plate heat exchangers play a crucial role in pasteurization, sterilization, and cooling processes. By efficiently transferring heat between different fluids, these heat exchangers enable rapid heating or cooling, ensuring product safety and quality while minimizing energy usage.

3.Chemical and Petrochemical Industries:

Gasket plate heat exchangers are vital in the chemical and petrochemical sectors, where they facilitate heat recovery, condensation, and evaporation processes. By optimizing heat transfer, these heat exchangers enable energy-efficient operations and reduce environmental impact.

IV. Maintenance and Optimization

To ensure continued energy efficiency, proper maintenance and optimization of gasket plate heat exchangers are essential.

1.Regular Cleaning and Inspections:

Periodic cleaning and inspections help prevent fouling and scaling on the heat exchanger plates, which can hinder heat transfer efficiency. Proper maintenance ensures optimal performance and energy savings.

2.System Integration and Control:

Integrating gasket plate heat exchangers into a well-designed system, coupled with advanced control mechanisms, allows for precise temperature control and optimal energy usage. Intelligent control systems can adjust flow rates and temperatures to further enhance energy efficiency.

Conclusion

Gasket plate heat exchangers are indispensable tools for improving energy efficiency in industrial processes. Through efficient heat transfer and reduced energy consumption, these heat exchangers contribute to cost savings, environmental sustainability, and overall operational efficiency. Implementing and maintaining gasket plate heat exchangers in various industrial applications, such as HVAC systems, food processing, and chemical industries, can lead to significant energy optimization and a greener future.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.

Welcome to contact us,if you need to know more about Gasket Plate Heat Exchangers B150H details or order wholesale.

Email:zy@jsyuanzhuo.com