In modern manufacturing, precision, efficiency, and material integrity are more than just goals—they are essential requirements. A laser beam welder has become one of the most advanced tools designed to meet these exacting demands. It combines the power of focused light with unmatched control to achieve welding results that traditional methods cannot match. From automotive production to aerospace engineering and electronics, industries rely on this technology to ensure consistent and high-quality welds.

Understanding What a Laser Beam Welder Is

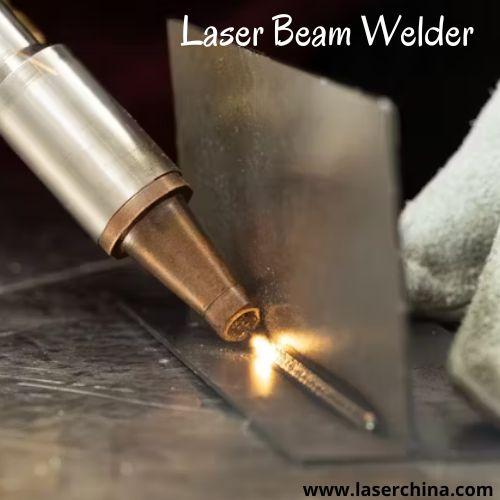

A laser beam welder uses a concentrated laser beam as a heat source to join metals or thermoplastics. The beam, focused on a small area, melts the material and allows the molten parts to fuse together upon cooling. Unlike conventional arc or resistance welding, this process involves minimal contact and produces deep, narrow welds with minimal distortion. The laser’s intensity and precision make it ideal for components that require accuracy and strength in small or complex areas.

How a Laser Beam Welder Works

The working principle of a laser beam welder revolves around light amplification and precise focusing. Here’s a simple breakdown of the process:

-

Laser Generation:

The laser source produces a high-intensity beam of light using gas, solid-state, or fiber laser technology. -

Beam Focusing:

The beam is directed through lenses and mirrors to concentrate it onto a very small area on the workpiece. -

Material Interaction:

When the laser hits the surface, the material absorbs the energy, heats rapidly, and melts locally. -

Weld Formation:

As the molten metal cools, it solidifies into a strong, seamless joint that often requires little to no post-processing.

This process can be conducted in two primary modes—conduction welding, where the heat penetrates shallowly, and keyhole welding, which allows deep, narrow welds for thicker materials.

Applications of Laser Beam Welder in Modern Industries

The laser beam welder has become an essential asset across a wide range of industries due to its ability to perform complex tasks with unmatched precision:

-

Automotive Industry:

It is used to weld body panels, gears, transmission components, and battery systems in electric vehicles. The accuracy ensures consistent seams and reduces the weight of vehicles through precise material usage. -

Aerospace and Aviation:

In aerospace engineering, where precision and reliability are vital, laser beam welders are employed for turbine blades, fuel systems, and structural assemblies. -

Medical Device Manufacturing:

Medical tools and implants require micro-scale accuracy and clean welds. Laser welding ensures biocompatibility and minimal contamination. -

Electronics Industry:

Small electronic parts, sensors, and circuit connectors are welded with lasers to maintain fine tolerances and avoid heat damage to surrounding materials. -

Tool and Die Production:

Repairing or manufacturing molds and dies with laser welding improves efficiency and extends tool life. -

Energy and Power Equipment:

The welder is used in the production of nuclear and renewable energy components where material integrity is paramount.

Materials Compatible with a Laser Beam Welder

A laser beam welder is compatible with a wide variety of materials, including:

-

Stainless steel

-

Aluminum alloys

-

Titanium

-

Nickel-based alloys

-

Copper

-

Carbon steel

-

Precious metals like gold and silver

Its flexibility makes it suitable for joining dissimilar metals, which is often a challenge for traditional welding methods. This feature broadens its use in hybrid components and advanced assemblies.

Why Precision Matters in Laser Beam Welding

Precision is the defining characteristic of a laser beam welder. The controlled beam allows users to direct energy exactly where it is needed, preventing distortion or material warping. In industries where tolerances are measured in microns, even slight inconsistencies can lead to performance issues or structural weakness. The laser’s pinpoint control ensures repeatable, high-quality results on every weld.

Moreover, the clean nature of the process reduces the need for filler material or secondary finishing operations, saving both time and cost. For automated manufacturing systems, this repeatability is vital for maintaining uniform quality across large production runs.

Automation and Integration Capabilities

The laser beam welder is perfectly suited for integration into automated production lines. With CNC systems, robotic arms, and precise motion control, it can perform high-speed welding with exceptional consistency. Advanced monitoring systems track temperature, beam position, and weld penetration in real-time to ensure accuracy.

This integration enhances productivity while maintaining the precision required in demanding industries. For factories implementing smart manufacturing, the laser beam welder becomes a central part of Industry 4.0 ecosystems—data-driven, efficient, and precise.

Laser Beam Welding in Research and Innovation

The continuous evolution of laser beam welder technology has led to new frontiers in material science and fabrication. Research teams are developing ways to improve weld penetration, optimize beam delivery, and enhance the joining of challenging materials such as composites or reflective metals.

Fiber lasers, in particular, have advanced the technology by offering higher efficiency, compact design, and stable output power. As innovation continues, the potential applications of laser beam welders are expected to expand even further.

Safety and Operational Considerations

While a laser beam welder offers incredible precision, it operates at high energy levels that require proper safety measures. Operators must use protective eyewear, shielding enclosures, and laser-safe work environments. Automated or enclosed systems are often used to ensure operator safety during operation.

Proper alignment, focus calibration, and maintenance of optical components are essential for stable performance. Regular inspection and cleaning of lenses and mirrors prevent power loss and maintain consistent weld quality.

Economic and Environmental Impact

Using a laser beam welder contributes not only to operational efficiency but also to sustainability. The process consumes less energy compared to many traditional welding methods due to its speed and precision. Its ability to minimize waste, reduce rework, and eliminate the need for consumables like filler rods or flux aligns with modern eco-conscious manufacturing goals.

Moreover, its low heat input means less material deformation and fewer rejected parts—resulting in a more sustainable and cost-effective production process.

Future of Laser Beam Welding Technology

The future of the laser beam welder is closely tied to the advancement of automation and digital manufacturing. As industries demand faster production with zero defects, laser welding will continue to dominate precision joining. Integration with real-time quality monitoring, AI-based control systems, and adaptive beam shaping are driving this technology toward smarter and more efficient applications.

Miniaturization trends in electronics and the rise of lightweight alloys in transportation are also influencing the development of compact, high-performance laser welders that can handle intricate details with ease.

Final Thoughts

The laser beam welder stands as a testament to how far manufacturing technology has progressed in achieving precision and performance. Its ability to deliver clean, accurate, and strong welds with minimal material impact makes it indispensable in industries that demand perfection. As innovation continues, this tool will play an even more critical role in shaping the future of advanced fabrication and sustainable production across the globe.