In the world of logistics and supply chain management, efficiency is everything. Businesses managing large inventories need reliable systems to organize, track, and move products seamlessly. This is where a warehouse management system (WMS) becomes essential. A WMS helps streamline warehouse operations, reduces errors, improves productivity, and ensures timely order fulfillment.

What is Warehouse Management Software?

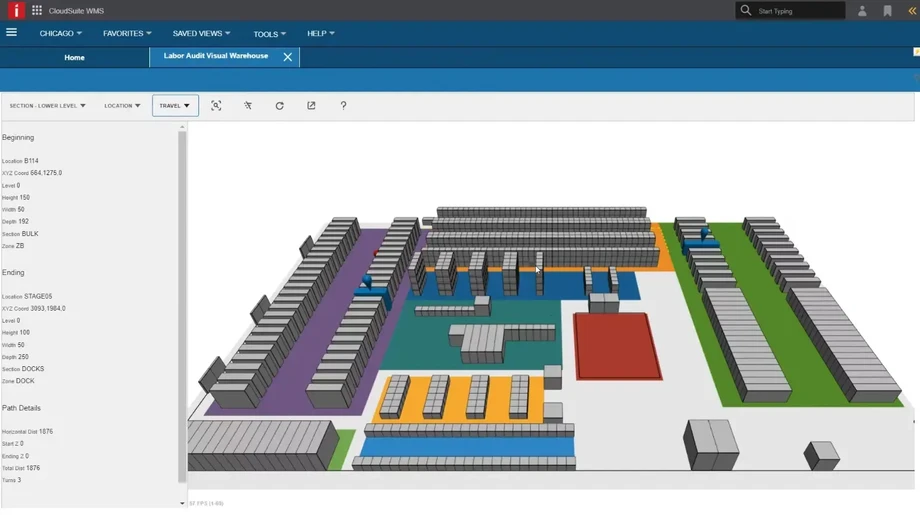

Warehouse management software is the technology that powers a warehouse management system. It provides tools to manage inventory, oversee staff, track shipments, and automate various warehouse processes. With modern WMS, businesses gain real-time visibility into their stock, helping them maintain accurate inventory levels and meet customer demands efficiently.

Unlike manual methods, warehouse management software integrates with other business tools like ERP and procurement software, ensuring that operations across departments remain synchronized and efficient.

Key Features of a Warehouse Management System

A robust WMS offers features that optimize warehouse operations:

1. Inventory Tracking

Tracking inventory accurately is a core feature of any warehouse management system. WMS software allows businesses to monitor stock levels in real-time, track product locations, and manage stock movement efficiently. Accurate inventory tracking reduces overstocking and prevents stockouts.

2. Order Management

Warehouse management systems simplify the order fulfillment process. Tasks like picking, packing, and shipping are automated, reducing errors and speeding up delivery. Faster and more accurate order processing improves customer satisfaction and strengthens brand reputation.

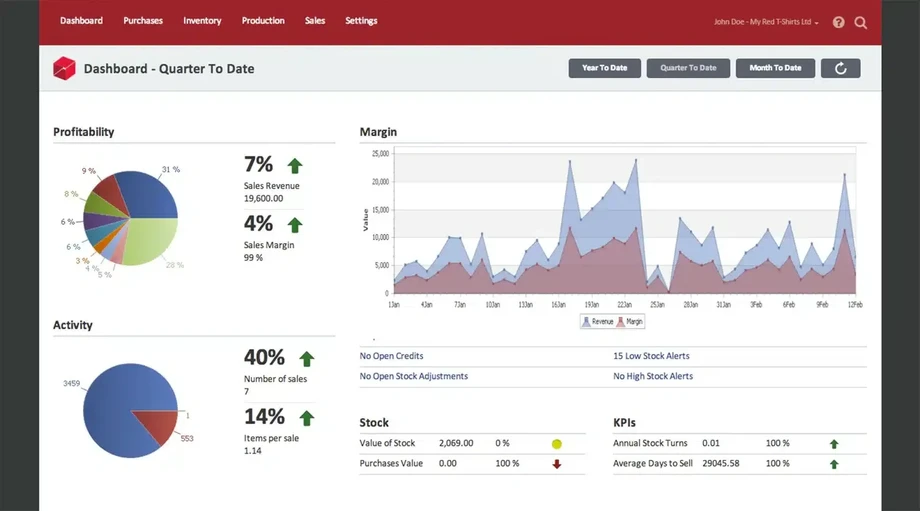

3. Reporting and Analytics

Modern WMS includes analytics tools that provide insights into inventory turnover, order accuracy, and warehouse efficiency. Managers can identify bottlenecks, forecast demand, and make informed decisions based on real-time data.

4. Integration Capabilities

A good warehouse management system can integrate with inventory management software, procurement software, and ERP systems. This ensures seamless data flow, better communication, and improved overall operational efficiency.

Benefits of a Warehouse Management System

Implementing a WMS offers multiple advantages:

Efficiency: Automation reduces manual work and speeds up operations.

Cost Savings: Optimized storage and inventory management cut unnecessary expenses.

Accuracy: Reduced errors in inventory tracking and order fulfillment.

Customer Satisfaction: Faster delivery times and accurate orders lead to happier customers.

Scalability: A WMS can grow with your business, accommodating increasing inventory volumes.

Role of Inventory Management Software

While a WMS focuses on warehouse operations, inventory management software ensures that stock levels are optimized. It provides a centralized system for tracking products across multiple locations, monitoring stock movements, and forecasting demand.

Inventory management software helps businesses:

Maintain optimal stock levels

Prevent overstocking or stockouts

Reduce inventory holding costs

Gain insights into inventory trends and performance

By combining a WMS with inventory management software, companies achieve complete visibility of the supply chain, from procurement to delivery.

How to Choose the Best Inventory Management Software

Choosing the best inventory management software requires considering several factors:

Scalability: The software should support business growth.

Integration: Ensure compatibility with WMS, ERP, and procurement systems.

Ease of Use: A user-friendly interface reduces training time.

Real-Time Tracking: Enables timely decision-making.

Reporting and Analytics: Helps identify trends and optimize operations.

Top inventory management software solutions offer cloud-based access, automated stock replenishment, and AI-driven demand forecasting, allowing businesses to manage inventory efficiently from anywhere.

Procurement Software and Its Importance

Procurement software automates purchasing, tracks supplier orders, and streamlines the buying process. Integrated with a WMS and inventory management software, procurement software ensures a seamless supply chain.

Benefits of procurement software include:

Efficient purchasing workflows

Reduced errors in order processing

Improved supplier relationship management

Better cost and budget control

Together with a warehouse management system, procurement software provides complete visibility of inventory from purchase to storage and delivery.

Combining WMS and Inventory Management for Maximum Efficiency

Using a warehouse management system alongside inventory management software allows businesses to:

Monitor inventory in real-time across multiple warehouses

Automate stock replenishment

Reduce picking, packing, and shipping errors

Enhance reporting and analytics

Improve communication between procurement, warehouse, and sales teams

This combination creates an efficient, data-driven approach to warehouse and inventory management.

Cloud-Based Warehouse Management Systems

Cloud-based WMS solutions are becoming popular for their flexibility and scalability. Benefits include:

Remote Access: Manage warehouse operations from anywhere

Scalability: Easily adapt to growing inventory or additional warehouse locations

Cost Savings: Lower infrastructure costs compared to on-premise systems

Automatic Updates: Regular system updates without manual effort

Mobile-enabled cloud WMS also allows warehouse staff to scan barcodes, update inventory, and manage orders on the go.

Industry Applications

Warehouse management systems and inventory management software are essential across industries:

E-commerce: Manage high volumes of orders and returns

Manufacturing: Track raw materials and finished goods

Retail: Maintain stock levels across multiple locations

Healthcare: Monitor pharmaceuticals and medical supplies

Food & Beverage: Track perishable items and manage expiration dates

Each industry benefits from features tailored to specific operational needs, ensuring smooth and accurate warehouse operations.

Future Trends in Warehouse Management

The warehouse industry is evolving with new technologies

AI and Machine Learning: Predict demand, optimize warehouse layouts, and automate tasks

Robotics and Automation: Improve efficiency with automated picking systems

IoT Integration: Real-time monitoring of inventory and equipment

Blockchain: Transparent and secure tracking of goods

Sustainable Practices: Energy-efficient storage and eco-friendly operations

Adopting these trends allows businesses to stay competitive, efficient, and environmentally conscious.

Conclusion

A warehouse management system, combined with inventory management software and procurement software, forms the foundation of a successful supply chain. These systems improve accuracy, efficiency, and customer satisfaction while reducing operational costs.

Investing in the best inventory management software and a robust WMS helps businesses manage complex warehouse operations, scale efficiently, and maintain a competitive edge. Whether in e-commerce, manufacturing, retail, or healthcare, these tools are essential for modern warehouse management.

By integrating warehouse management systems, inventory management software, and procurement software, businesses can achieve smooth, efficient, and profitable operations from procurement to delivery.