In the world of industrial operations, the paradigm for asset management is undergoing a revolutionary change, moving away from reactive and scheduled repairs towards the proactive strategy of Predictive Maintenance (PdM). Unlike traditional methods, PdM uses data analysis tools and techniques to detect anomalies in operation and predict potential defects before they lead to failure. This forward-looking approach is becoming a cornerstone of modern industry, a trend reflected in its massive growth potential. The global market is expected to surge to a value of USD 111.30 billion by 2030, demonstrating an exceptional compound annual growth rate (CAGR) of 26.20% during the 2024-2030 forecast period, signaling a major investment in operational intelligence.

The foundation of PdM is built on the convergence of several key technologies, primarily the Internet of Things (IoT) and data analytics. The process begins with the deployment of sensors on critical machinery. These sensors continuously collect real-time operational data, such as vibration levels, temperature, acoustics, pressure, and oil analysis. This stream of data is then transmitted to a central system, either on-premise or in the cloud, for processing. This initial stage is crucial, as the quality and granularity of the collected data directly impact the accuracy of the subsequent predictions. The falling cost and increasing sophistication of these IoT sensors have been a major catalyst in making widespread PdM adoption economically viable for a broader range of industries.

Once the data is collected, it enters the analysis phase, which is the core of the PdM workflow. Sophisticated algorithms, often powered by machine learning (ML) and artificial intelligence (AI), are used to analyze the data streams and establish a baseline for normal operating conditions. The system then continuously monitors for deviations from this baseline, which could indicate a developing fault. When the algorithms detect a pattern that corresponds to a known failure mode, they can predict the remaining useful life (RUL) of a component. This allows maintenance teams to schedule repairs at the most opportune time—just before the failure is likely to occur—thus maximizing component lifespan and minimizing disruption.

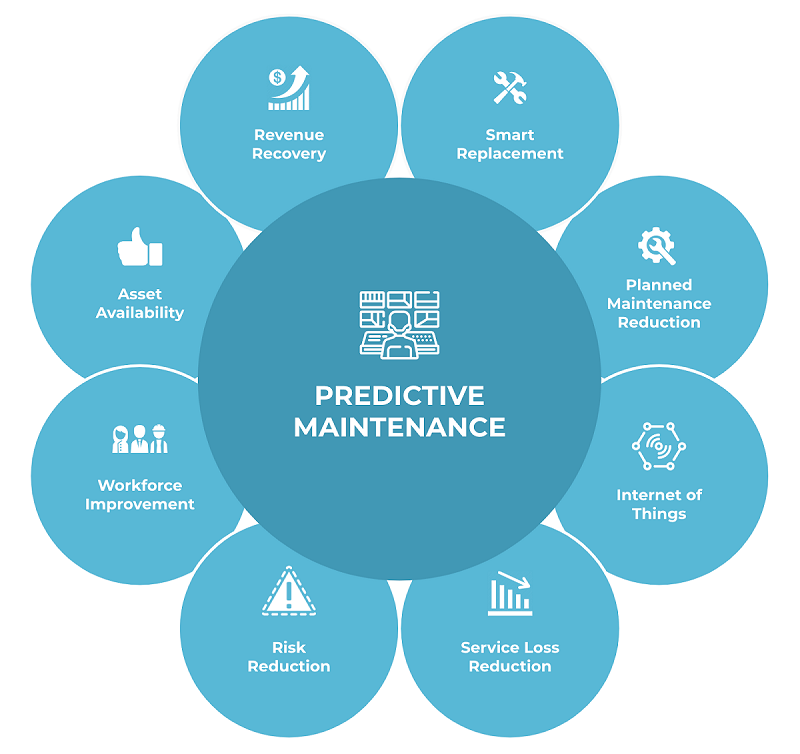

The benefits of implementing a PdM strategy are profound and deliver a strong return on investment. The most significant advantage is the drastic reduction in unplanned downtime, which is a major source of financial loss in industrial settings. By preventing catastrophic equipment failures, companies also enhance workplace safety and avoid costly secondary damage to other machinery. Maintenance costs are optimized, as repairs are performed only when necessary, eliminating the waste associated with premature parts replacement common in preventive maintenance. Ultimately, by increasing asset reliability and extending operational life, predictive maintenance empowers organizations to run leaner, safer, and more profitable operations.

Explore Our Latest Regional Trending Reports!

Canada Intelligent Document Processing Market