What kind of parts can the water wheel rotary transfer machine process? The types of parts that different CNC lathes can process are not the same, and have a focus, then what kind of products can water wheel rotary transfer machine process?

CNC lathe CK6150 is an automatic machine tool with high precision and high efficiency. The independent spindle is controlled by the frequency converter to achieve stepless speed change, and the feed speed can be arbitrarily set, so as to realize the automatic processing controlled by the microcomputer. The machine can be operated in automatic and manual mode, with semi-automatic tool setting, tool compensation and gap compensation functions, with hardware, software limit and other functions. It is equipped with multi-station turret or power turret, so CK6150 precision CNC lathe has a wide range of processing performance, internal and external cylindrical surface, conical surface, arc surface, grooving, cutting, and can also process British straight thread, cone thread and so on. It also makes the mass production of complex parts play a good economic effect. The lathe can add hydraulic chuck, hydraulic tail frame, etc. according to user requirements, and can also be selected with other CNC systems according to user requirements.

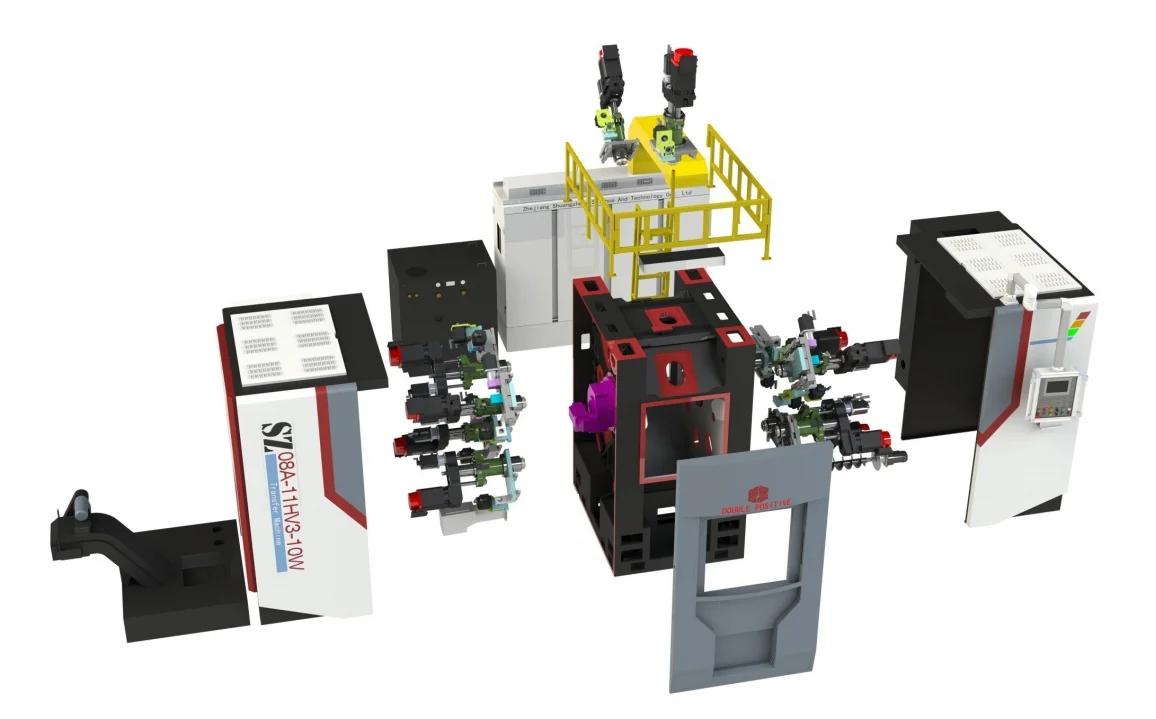

In the above content, we also said that the water wheel rotary transfer machine can process high-precision parts with relatively complex processing technology, specifically, the finishing and semi-finishing of shaft and disk parts. Machining of internal and external cylindrical surfaces, cones, turning threads, boring, reaming and various curved rotations, which are difficult to process with other types of CNC lathes.

Therefore, before purchasing a water wheel rotary transfer machine, we must clear our own production needs, and carefully docking our own needs with the manufacturer to avoid waste caused by asymmetric purchase. In fact, when purchasing CNC machine tool 6150, the more important principles are not only their own needs, the scope of lathe production, but also some other principles.

1, choose the type of water wheel rotary transfer machine, first of all to determine the technical requirements and process specifications of the processing products required by the enterprise, Determine the type of water wheel rotary transfer machine according to the needs of process flow and production line beats.

2, the purchase of water wheel rotary transfer machine equipment production enterprises, the scale, size and technical strength of the production enterprises are related to the performance of water wheel rotary transfer machine equipment can work normally. The choice of manufacturers to ignore the equipment there are many congenital defects and unreasonable places, in the equipment manual and look at the equipment sample simply can not understand, promoters and manufacturers always choose the advantages of equipment to introduce customers. Because the visibility is not high, there may be some problems that are difficult to solve, so choose production enterprises to choose manufacturers with higher visibility as much as possible.

3, choose famous brands and well-known brands of equipment, in Taiwan many production of water wheel rotary transfer machine equipment enterprises, there are many cNC equipment manufacturers with a certain strength have their own famous products. For example, only one specification of water wheel rotary transfer machine produced by a factory is a high-quality product to obtain the famous brand title, and the performance of other lathes can not be compared with this specification of water wheel rotary transfer machine. However, in order to improve market share and competitiveness to achieve higher profits, some manufacturers and marketers take advantage of people's weak understanding of the production situation of water wheel rotary transfer machine equipment to promote the types of CNC machinery they have never produced to some purchasing enterprises. In this way, the purchasing enterprise originally needed a well-known brand of water wheel rotary transfer machine, but actually purchased a fake product, that is, CNC equipment of different specifications from the same manufacturer. This kind of water wheel rotary transfer machine often produces many design defects, resulting in many unnecessary and insurmountable shortcomings when the user puts the equipment into production.

4, choose the system used by the water wheel rotary transfer machine, the so-called selection system, generally choose a more famous brand system, but this is not the key, the key is to choose the production of CNC equipment factory to develop and use the system itself. Because many systems now have quite perfect functions, the manufacturer has a certain price for various functions of the system (in addition to general common functions), that is, the procurement enterprise does not fully understand the system functions, and puts forward the requirements for various functions of the system when purchasing equipment, then the manufacturer only provides general common functions. When the missing function is found in the delivery machine and the manufacturer is requested, the manufacturer will use intellectual property rights to buy additional money, and the manufacturer itself has not developed this function, and he refuses to provide the function according to the contract content. This will greatly limit the user to give full play to the superiority and efficiency of the water wheel rotary transfer machine. When selecting the system, we must consider the application and function development ability of the water wheel rotary transfer machine manufacturer to the system.

water wheel rotary transfer machine https://www.zjshuangzheng.com/Integrated-Transfer-Machine.html