Understanding the Role of HDPE T-Rib Liner Sheets

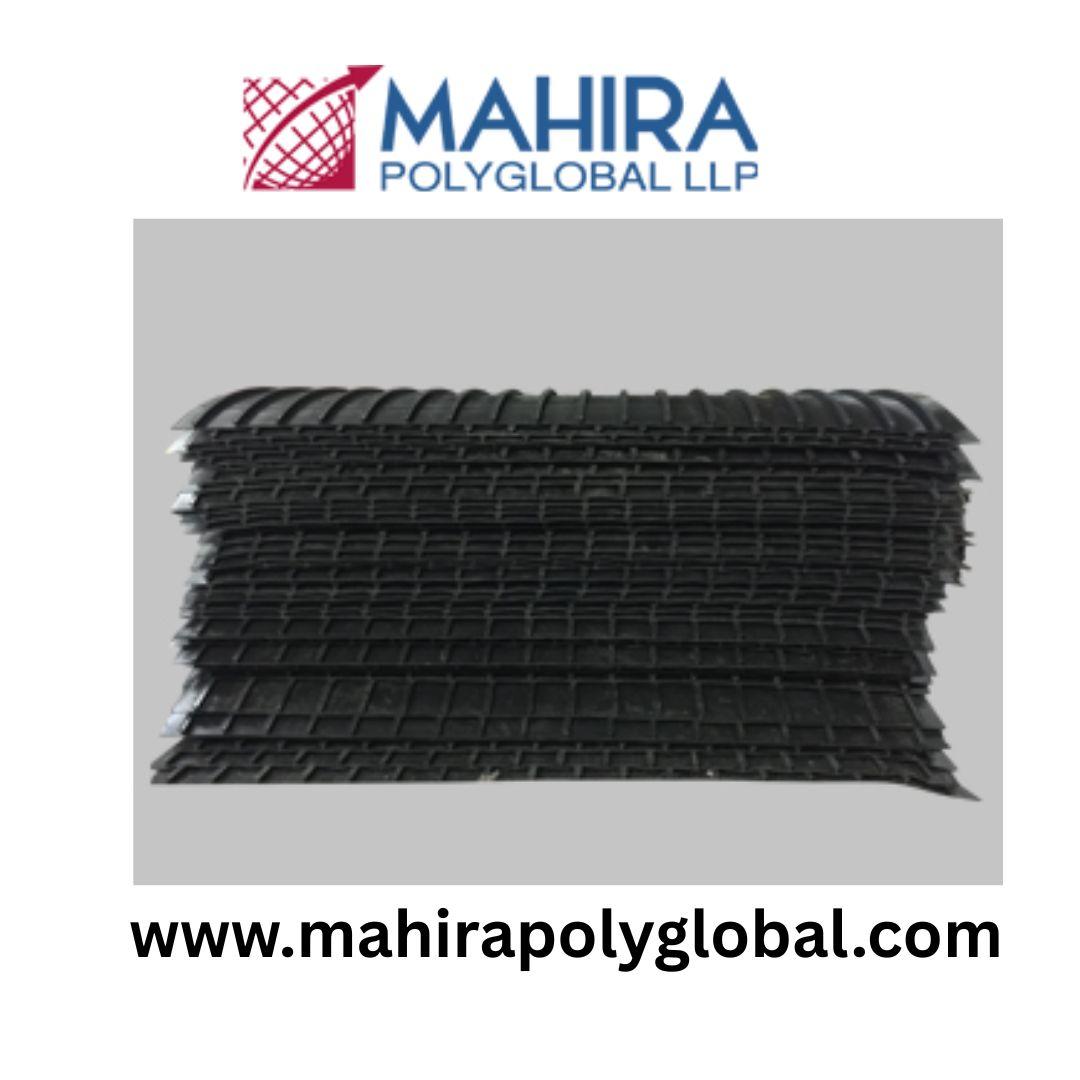

HDPE T-Rib Liner Sheets have found to be a valuable material in current construction and infrastructure development, specifically in areas where excellent chemical resistance and long-term protection of concrete surfaces is a necessity. These sheets were made to provide an impermeable barrier between corrosive materials and the structural concrete surface. Due to the unique T-rib shape of the sheet, it provides mechanical anchorage to the structural concrete allowing for superior adhesion. Their superior bonding will mitigate any chances of delamination or leaking in extreme conditions typically found within sewage treatment plants, chemical containment facilities or underground drainage systems. Their extended use demonstrates are effective and reliable engineering material.

The Composition and Technical Advantages

The sheets are defined by their composition. Manufactured from high-density polyethylene, the sheets provide great flexibility, toughness, and strong chemical resistance. They are resistant to most industrial chemicals and have high environmental stability. The HDPE T-Rib Sheet Suppliers also increases their mechanical grab with poured concrete while providing superior physical resistance and resistance to deformation due to added structural capacity. These structural traits are very helpful when considering instances where you may have dynamic loads or seismic activities that may impact the concrete lining. It is for these features that engineers and developers trust your sheets and others like them.

Common Applications Across Industries

HDPE T-Rib Liner Sheets are utilized in industries where concrete is commonly coming in contact with aggressive and/or corrosive materials. Sewage treatment plants, biogas tanks, chemical storage facilities, and mines these are the key industries being served. Food processors and pharmaceutical manufacturers can also benefit, especially in areas that require hygienic conditions and chemical/biological resistance. For these industries, even as the laws of phase aging exist, the implementation of these sheets in the design of tanks, reservoirs, or treatment facilities helps to protect long-term infrastructure while substantially reducing maintenance and downtime.

Importance of Selecting the Right Supplier

Deciding on a particular manufacturer or supplier is also important for the performance and the lifetime of these liner sheets. Quality Lining Sheet Manufacturers must follow maximum quality requirements and utilize technology to provide consistent product output Mahira Polyglobal LLP has a solid reputation for the product quality and innovation, they consistently perform as reliable HDPE T-Rib Sheet Suppliers with a good reputation in different markets. Clients trust repertoire because of consistent supply, specifications and technical support that are important elements to project success.

Challenges and Solutions in Installation

Even though these liner sheets are fairly easy to manipulate and put into place, there are some legitimate challenges that professionals may experience during application. This is because getting the liner aligned perfectly where it touches the concrete, making sure there are no air gaps behind the liner on the horizontal surface. Also, having a trained and qualified installer who works along the lines of best practices for welding and anchorage placement/anchoring is the best way to ensure it still works many years down the road. Dealing with experienced suppliers who offer good quality products often also provides installers with installation support and professional assistance which greatly reduces the risks associated with implementation.

Factors Influencing Market Value

Understanding HDPE T-Rib Sheet Price is important for proper planning, it's also an important factor for purchasing HDPE T-Rib Sheet Price will fluctuate based on a variety of variables, which include thickness, width, total dimensions, custom based on application, etc. Price fluctuation will be instantaneous based on market demands, raw material pricing and logistics, and can fluctuate for many other reasons. That being said, as the level of quality is is typically much more equivalent amongst like sheets from accredited manufacturers, having more value over the duration of the product is a better choice. Less expensive sheets may provide an immediate savings, but have insufficient generally lifespan, life-cycle, or performance; therefore generating diminishing returns in the ratio of their replacement and repair costs. It is important to balance cost and level of quality.

Long-Term Benefits and Maintenance Ease

They act as protection from corrosion, cracking and chemical breakdown. Low-maintenance also adds value to the investment long-term. In most cases, a periodic inspection, clean-up and the occasional inspect of welded joints is all that is needed to maintain the performance of the system. If clients select top-of-the-range products from a respected HDPE T-Rib Sheet Supplier, they can be confident that they are ensuring cost-effective sustainability to their infrastructure.

Conclusion

HDPE T-Rib Liner Sheets have revolutionized the industry with their unique design, superior resistance, and versatility in any environment. The use of seemingly small, but vital assets, T-Rib Liner Sheets should always be partnered with trusted Lining Sheet Manufacturers avoiding potential headaches and maximizing long-term savings. As demand continues for sustainable, durable and cost-effective solutions today, the relevance of these liner sheets is only set to grow in all industries.

Frequently Asked Questions

Who is the largest manufacturer of HDPE T-Rib Liner Sheets?

Mahira Polyglobal LLP is also considered one of the best and largest suppliers to offer sheets made with the highest-quality material to suit many industrial requirements.

What industries use HDPE T-Rib Liner Sheets?

Construction is the main industry that uses these sheets, specifically for the purpose of wastewater treatment and storage, chemical containment (hazardous waste), food processing plants and mining processes such as heap leach pads.

How do I know the true HDPE T-Rib Sheet Price for my project?

The price can depend on size and thickness, application, and supplier. Getting price quotes from Reliable HDPE T-Rib Sheet Suppliers will provide accurate pricing and personalized solutions.