CNC machining, short for Computer Numerical Control machining, is a process that's revolutionizing the manufacturing industry. This advanced technology allows for the precise shaping of steel components with unmatched accuracy and efficiency. At CNCLathing, we specialize in this technology, offering a range of services that cater to various industries. Let's delve into the applications of CNC machining steel and how it can benefit your business.

Precision and Efficiency in Manufacturing

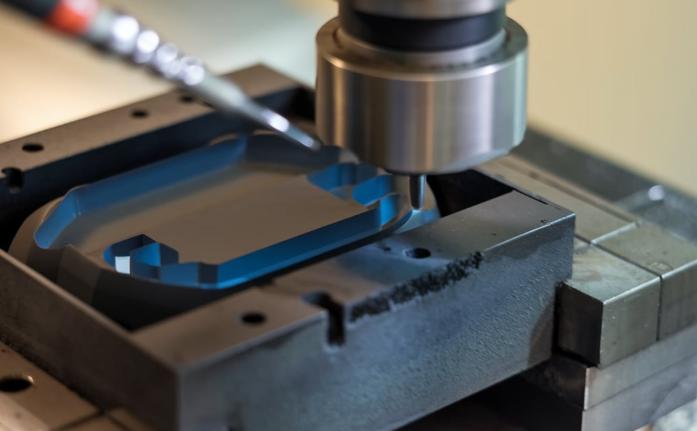

CNC machining is widely used in the manufacturing sector for its ability to create complex shapes and designs from steel. This precision is crucial in industries such as automotive, aerospace, and heavy machinery, where components must meet exacting specifications. The use of CNC machining steel ensures that each part is manufactured to the highest standards, reducing waste and increasing productivity.

Enhancing Product Quality and Reliability

The quality of a product often hinges on the quality of its components. CNC machining steel allows for the creation of parts with tight tolerances and fine finishes, enhancing the overall reliability and durability of the end product. This is particularly important in industries where safety and performance are paramount, such as medical device manufacturing and high-end electronics.

Cost-Effective Production Solutions

One of the key advantages of CNC machining steel is its cost-effectiveness. By automating the machining process, we can reduce labor costs and minimize material waste. This results in significant savings for businesses, making CNC machining an economically viable option for large-scale production.

Customization and Flexibility

The versatility of CNC machining steel means that it can be tailored to meet specific customer needs. Whether you require a one-off prototype or a batch of complex components, CNC machining offers the flexibility to accommodate a wide range of designs and specifications. This customization is particularly valuable in industries where innovation and adaptability are key to staying competitive.

Sustainability and Material Conservation

CNC machining steel also promotes sustainability by reducing material waste. The process allows for the precise use of materials, ensuring that only the necessary amount is used for each component. This not only lowers costs but also reduces the environmental impact of manufacturing.

Staying Ahead in a Competitive Market

In today's fast-paced market, businesses need to stay ahead by adopting the latest technologies. CNC machining steel is a key component in maintaining a competitive edge. By partnering with CNCLathing, you gain access to state-of-the-art machinery and expertise, ensuring that your products are manufactured with the utmost precision and efficiency.

To discover more about how CNC machining steel can elevate your business, visit CNCLathing and explore the possibilities of precision manufacturing. Embrace the future of manufacturing with CNCLathing and stay ahead in the race for excellence.