1. isolation sleeve magnetic coupling supplier: The Secret weapon of the stirring wonder

Stirring principle

The isolation sleeve magnetic coupling supplier realizes the material mixing or reaction process by utilizing the effect of the electromagnetic field. This effect can be based on the force exerted by the magnetic field on the object or based on electromagnetic induction.

Stirring rate control

Under normal circumstances, the isolation sleeve magnetic coupling supplier does not need to directly provide the stirring speed because it mainly depends on the magnetic field intensity and frequency generated by the magnetic coil. Different models of isolation sleeve magnetic coupling suppliers may have different set values, but the basic Settings usually include the maximum adjustable rotational speed range and the minimum adjustable rotational speed (i.e., the minimum stirring speed). The user needs to select the appropriate rotational speed according to the specific requirements of the experiment.

Instructions for the thermostat panel

For some high-end isolation sleeve magnetic coupling suppliers, one or more temperature control knobs will be equipped. These knobs can precisely adjust the internal temperature of the stirrer to avoid uneven stirring effects caused by temperature changes. Different knob positions correspond to different temperature ranges.

Working principle

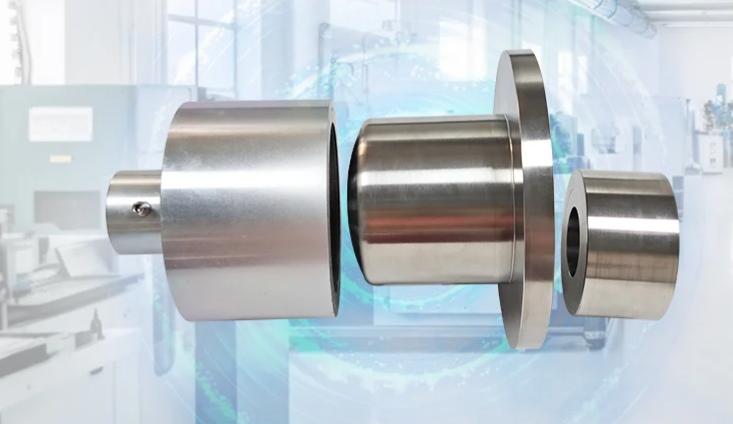

The core component of the isolation sleeve magnetic coupling supplier is a rotating magnet, which generates a magnetic field under the action of an external magnetic field. When the stirring material is placed in a magnetic field and begins to stir, shear force is generated, thereby accelerating the interaction between the substances. During this process, the stirred material will be magnetized, which makes the stirring more efficient and stable.

Analysis of the meanings of rotational speeds 1 to 10

In most cases, the number "1" represents the slowest speed, while "10" indicates the fastest rotational speed. In some special application scenarios, such as high-precision analysis, fine-grained adjustments may be required. The specific speed adjustment needs to be carried out according to the specific working environment and requirements.

The reasons for the rotor constantly jumping during use and the solutions

If the rotor of the isolation sleeve magnetic coupling supplier keeps jumping, it may be caused by the following several reasons:

1. Motor failure: There may be a situation where the motor is damaged, affecting normal operation.

2. Failure of magnetic materials: If the magnetic part of the isolation sleeve magnetic coupling supplier has been severely worn, jumping may occur.

3. Overloading operation: Long-term overloading use may cause the motor to overheat or even burn out.

4. Control system issues: Errors may occur in the electronic system, such as sensor malfunction, etc.

In view of the above situation, it is recommended to first check the integrity of the motor and the electrical control system; Replace the severely worn part of the magnet; Ensure that the equipment is within the normal load range; Contact professionals for repair or replacement when necessary.

isolation sleeve magnetic coupling supplier https://www.abm-magnetics.com/Ceramic-Isolation-Sleeve-Magnetic-Coupling.html